Custom Beer Tanks from 1 BBL to 100 BBL

We design and build beer fermentation tanks that are perfect for a wide range of industries. You can change our tanks to make beer, fruit beer, cider, wine, and other drinks. We can provide equipment that meets your exact needs, whether you need fabrication based on your own design or a complete turnkey solution that works with your brewing technology.

Fermentation is the most important part of making beer. A reliable fermentation tank is necessary for all types of breweries, from small home ones to big ones.

We have the right design for every use, whether it’s synthetic or stainless steel, pressurized or not, cylindrical, conical, or oval.

We have a wide range of beer tank, from 50L to 30000L, so you can find the right one for your brewing needs.

Our beer tanks ship to any city worldwide and include door-to-door installation.

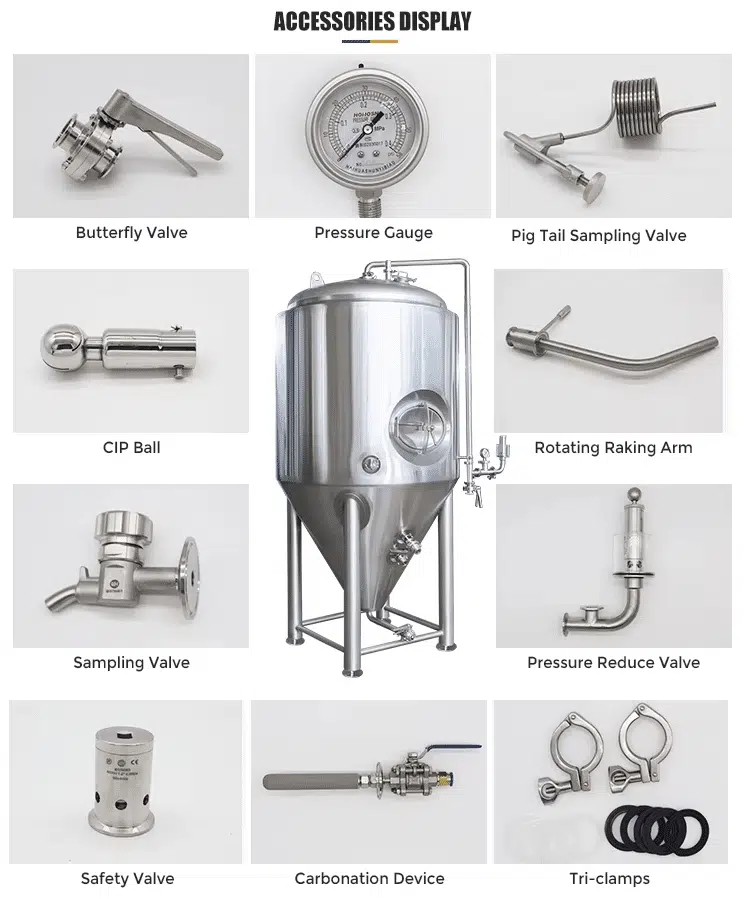

Beer Fermentation Tank Standard Configuration

- Material: 304/316 stainless steel, suitable for food use

- Cooling System: Double-wall construction with cooling jackets that are dimpled on the shell and cone

- Access: side shadowless manhole or top pressure manhole

- Temperature Control: high-precision sensor-equipped PT100 thermowell

- Racking: The cone’s rotating racking arm

- Dry Hopping: adding port to 4″/6″ dry hops

- Cleaning: CIP spray ball with 360-degree coverage

- Cooling Connections: Inlet and outlet threaded ice water

- Safety and Monitoring: tank-top safety valve and gauge-equipped pressure relief valve

- Structure: Sturdy legs with lifting bars on the tank edge and bolts that can be adjusted

Specifics of the Design:

- Yeast dumping outlet at 60° for effective discharge

- Oversized headspace for active fermentation of 25%

- Easy quality checks with a fully hygienic tri-clamp sampling valve

Our Factory Video

Technical Benefits of the Ace beer tank

- Easy to Install: Comes with lifting ears for safe and easy hoisting.

- Dimpled cooling jackets make sure that heating and cooling work at their best.

- Optimized Headspace: 25% more headspace with a cover volume that is calculated separately for active fermentation.

- Custom Access: Choose between a side or top manhole to fit your brewing process.

- Pressure Tested: The jackets were tested at 5Bar/0.5Mpa and the internal shell at 4Bar/0.4Mpa. The results are clearly written down on a data plate.

- Polished, brushed, mirror finish, or pickling passivation are all available upon request.

- Stable Setup: All tanks have adjustable bolts that let you line them up and level them exactly how you want.

- Yeast Management: The 60° cone angle is meant to help yeast flow out quickly.

- Operator-Friendly: Bigger tanks come with a special ladder that makes it safe and easy to use.

Send us a message

Any question or inquiry will be replied within 24 hours.

Frequently Asked Questions

Q:Are you a manufacturer?

Yes, we have been in providing the professional products in this field for 22 years.

Do you provide customized service

We can design the beer tank according your requirements, at the same time we will give you our professional suggestion, as you know, we have been in this industry for many years.

What is your terms of payment?

T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We’ll show you the photos of the products and packages before you pay the balance.

What is your terms of delivery?

Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

May I become your agent in our country?

If you are also in this industry, we warmly welcome you to become our agent.

Where is your factory located?

Our factory is located in Wenzhou, China, just a 10-minute drive from Wenzhou Airport. We warmly welcome you to visit our facility.