Beer brewing has become a popular hobby in the United States, with more than 1.1 million Americans making their own beer at home. Knowledge of the beer brewing process is essential if you want to make good brews. Each stage should be well understood for better control over the final product. Do not be afraid to try brewing your own beer if you are new in this area. The craft beer movement has reignited interest in beer culture and homebrewing as an art form; many people find that going from raw ingredients to finished drink is both rewarding and educational.

Understanding the Basics

What is Beer Brewing?

Definition & History

Beer brewing refers to producing alcohol by fermenting starches derived mainly from cereal grains such as barley malt or wheat flour. The earliest evidence of brewing dates back to ancient civilizations like Babylon where they brewed more than twenty kinds around 3,000 BC; it was also highly regarded among ancient Egyptians who used it not only as an offering for gods but also as medicine against different diseases. It originated some 5 millennia ago in southern Babylonia located between two rivers – Tigris and Euphrates — known today as Iraq during what historians call Prehistoric times (around 3rd millennium BCE). Monastic breweries were common throughout Europe during Middle Ages while central Europe became major power house in 13th Century after hop flavoring came into use during 9th Century.

Types of Beers

Beers come in different flavors which are mostly dictated by their types or categories; there can be ales, lagers, stouts, porters etcetera. But basically we have two main divisions: ale yeast works best at higher temperatures giving rise to fruity flavors while lager yeast works well under cooler conditions resulting into cleaner tastes without any fruity esters being produced during fermentation process other than those associated with diacetyl formation which may cause buttery off flavors if left unchecked. Stouts and porters are dark in color due roasted malt used during brewing , they also contain higher levels of sweetness than other beers because caramelization takes place when heating wort while wheat beer is brewed with large proportions of wheat giving it light refreshing characteristic.

Equipment

Brewing Kit

A brewing kit usually consists of a fermenter, airlock, thermometer, hydrometer and siphon. The fermenter is where the sweet liquid (wort) sits during fermentation process. An air lock lets out carbon dioxide produced by yeast which eats up sugars in wort to produce alcohol but prevents entry into container any contaminants that may spoil your brew while thermometer helps you keep track of temperature levels within optimal ranges required for yeast activity – this can be done without one too by just using touch sense . A hydrometer measures how dense or thick wort has become after conversion of sugars into alcohol; if reading drops significantly then most likely all available sugar content have been converted into ethanol hence alcoholic concentration is high enough. Wort transfer from one vessel another without disturbing sediments could easily be achieved through use a siphon tube.

Additional Tools

Other necessary items include brew kettle, wort chiller, grain mill and mash tun. A brew kettle is needed for boiling hops together with malted barley which gives flavor bitterness as well color to final product known as beer while wort chiller helps cool down hot liquid rapidly after boiling so as to prevent contamination by wild yeast organisms found in air around us; these two should never miss from your list if serious about making great tasting beers at home . Grain milling machine crushes grains improving on enzymatic reactions between water soluble starches contained within them thus allowing efficient conversion into sugars during mashing stage ; this could also be done manually using wooden spoon but it will take much longer time since surface area exposed enzymatic action would small compared when mechanical means employed .

Key Ingredients

Malt

Brewing sugar comes from malt. Barley is the most widely used grain for malting, although other grains can be used. Malting involves soaking barley in water, allowing it to germinate, then drying it in a kiln. Beer gets different flavors, colors, and body from different types of malt. Most beers are made with pale malt as the base but caramel or chocolate malt can be used for extra complexity.

Hops

Hops provide bitterness, flavor and aroma to beer. The hop plant has cone-shaped flowers that contain resins and essential oils. These compounds help balance the sweetness of the malt with their unique flavors and aromas while also acting as a natural preservative. Brewers add hops at various stages during brewing to achieve desired levels of bitterness and aroma.

Yeast

Yeast is a microorganism that converts fermentable sugars into alcohol and carbon dioxide gas (CO2). There are two main types of yeast used in brewing: ale yeast and lager yeast. Ale yeast ferments at higher temperatures producing fruity esters which contribute complex flavors while lager yeasts ferment colder resulting in clean crispness. Yeast choice greatly affects final beer flavor profile.

Water

Water accounts for most of what’s inside your glass when you drink beer! The quality of water used affects both how well brewers can make their product as well as what ends up coming out at the end too . Different styles benefit from certain minerals being present or not so much so depending on where they originated Pale Ales may need more sulfate than others to bring out hop bitterness etc… It all depends but treating water right ensures consistent quality throughout each batch produced!

Reference Video

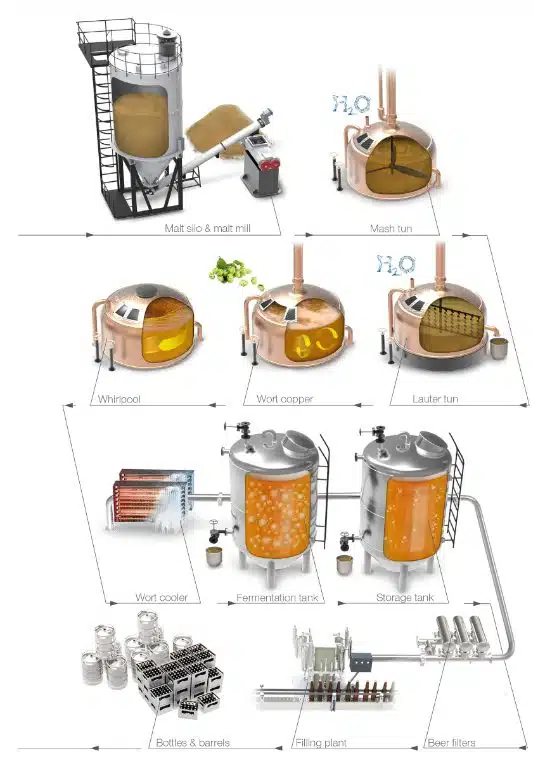

The Beer Brewing Process

Step 1: Malting

What is Malting?

Malting is when raw barley gets converted into malted barley which serves as a major ingredient in brewing beer. First step involves soaking the barley in water before it germinates. Enzymes come alive during germination and start breaking down starches into fermentable sugars that can be used by yeast later to produce alcohol and carbon dioxide gas. The next thing done is drying out this malted grain inside dryers like kilns where flavors are developed as well as colors added.

Types of Malt

Different malts will give different characteristics to beer. Most beers use pale malt because it has a neutral flavor profile which makes good base for many styles. Caramel malt on other hand adds sweetness while also giving some depth in terms of color; chocolate malt provides strong roasted taste but too much could make your brew bitter so you need balance here! It all depends on what kind of beer you want at the end.

Step 2: Milling

Milling Process

After malting, grains need to be milled so that enzymes can easily access starches during mashing process. This is achieved by crushing them into small particles with help from grain mill which increases surface area for better enzyme action upon mixing with hot water later on . It should also be noted that consistency matters most when it comes to grinding because uniformity allows even extraction during lautering phase thereby getting more fermentable sugars out.

Equipment Needed

A miller will require a grain mill for milling process . There are different types of mills depending on the size and volume required in each batch produced e.g roller mills used by homebrewers crushes grains between two rollers producing consistent grind necessary for efficient mashing; coarseness settings can be adjusted thus controlling crush level etc

Temperature Regulation

It is important to regulate temperature when mashing. Different enzymes have different working temperatures which are ideal for them. Beta-amylase functions best at around 140-150°F, where it produces fermentable sugars; while alpha amylase works optimally at 155-165°F and creates dextrins that give body to beer too. Keeping the right temperatures ensures that desired quantities of nonfermentable sugars are produced alongside those fermentable ones.

Step 4: Lautering

What is Lautering?

Lautering is a process used in brewing which separates liquid wort from solid grain husks after mashing has taken place. The mashed mixture is transferred into a vessel called a lauter tun fitted with a false bottom through which only liquids can penetrate leaving behind solid grains such as malted barley or wheat etc., depending on what type of beer you want to make. The main aim here is to extract all possible amounts of fermentables from the mash so that they may be later fermented into alcohol by yeast during fermentation process

Techniques

Several techniques improve lautering efficiency. The most common method is sparging. Sparging involves rinsing the grains with hot water to extract additional sugars. There are two main types of sparging: batch sparging and fly sparging. Batch sparging adds water in stages, draining the wort between each addition. Fly sparging continuously adds water while draining the wort. Both methods aim to maximize sugar extraction without over-extracting tannins, which can cause bitterness.

Step 5: Boiling

Adding Hops

Boiling the wort serves multiple purposes. One of the most important steps during boiling is adding hops. Hops contribute bitterness, flavor, and aroma to the beer. Brewers add hops at different times during the boil to achieve desired characteristics. Early additions primarily provide bitterness. Later additions enhance flavor and aroma. The timing of hop additions plays a crucial role in the final profile of the beer.

Boiling Time

The boiling time typically ranges from 60 to 90 minutes. Boiling sterilizes the wort, killing any unwanted microorganisms. It also evaporates unwanted volatile compounds. The length of the boil affects the concentration of the wort. A longer boil results in a higher concentration of sugars, leading to a higher alcohol content in the final beer. Monitoring the boil time ensures consistency and quality in the beer brewing process.

Step 6: Fermentation

Fermentation Vessels

Fermentation transforms the wort into beer. This step requires a fermentation vessel. Common vessels include glass carboys, plastic buckets, and stainless steel fermenters. Each type has its advantages. Glass carboys are easy to sanitize and do not retain odors. Plastic buckets are lightweight and affordable. Stainless steel fermenters offer durability and ease of cleaning. Choosing the right vessel depends on the brewer’s preferences and budget.

Yeast Pitching

Yeast pitching involves adding yeast to the cooled wort. Proper yeast pitching is crucial for a successful fermentation. The amount of yeast required depends on the wort volume and gravity. Under-pitching can lead to a sluggish fermentation, while over-pitching can cause off-flavors. Rehydrating dry yeast or creating a yeast starter for liquid yeast ensures healthy yeast cells. Distributing the yeast evenly throughout the wort promotes consistent fermentation.

Fermentation Time

Fermentation time varies based on the beer style and yeast strain. Primary fermentation usually takes one to two weeks. During this period, yeast converts fermentable sugars into alcohol and carbon dioxide. Monitoring the fermentation temperature is essential. Different yeast strains have optimal temperature ranges. Maintaining the correct temperature ensures proper yeast activity and flavor development. After primary fermentation, some beers require additional conditioning time to mature and develop complex flavors.

Step 7: Conditioning

What is Conditioning?

Conditioning refers to the maturation phase in the beer brewing process. This step allows the beer to develop its final flavor profile and carbonation level. Conditioning also helps to clarify the beer by allowing yeast and other particles to settle.

Methods of Conditioning

Brewers use several methods for conditioning beer. The most common method involves transferring the beer to a secondary fermenter. This vessel provides a clean environment for the beer to mature. Another method, known as bottle conditioning, involves adding a small amount of sugar before bottling. The residual yeast ferments the sugar, producing carbon dioxide and natural carbonation. Keg conditioning follows a similar process but occurs in a keg instead of bottles.

Step 8: Filtration

What is the reason for filtration?

Filtration removes unwanted particles from beer. This stage is aimed at improving the brightness and stability of the final product. It also enhances its appearance and mouthfeel. Some types of beers require more filtering than others.

Methods of filtration

There are several filtering methods in the brewing process of beer. One of them involves using a plate filter. A device passes beer through a series of filter pads to remove particles from it. Another method uses a cartridge filter, which has a porous membrane that traps solid matter. Homebrewers often use simple gravity filters where beer is pulled down by gravity through a filter medium. Each method provides different levels of filtration that affect clarity and texture in finished beers.

Step 9: Bottling

Cleaning Bottles

One important step in the process of brewing beer is cleaning bottles. If not, contaminants may ruin it and produce a bad taste. To sterilize them, brewers use boiling water or sanitizing solutions. It is necessary to sanitize each bottle so as to prevent any kind of contamination.

Procedure For Bottling Beer

The bottling process starts with racking the conditioned beer into a bottling bucket. A siphon is used to move the beer without disturbing the sediment. Then brewers fill every bottle, leaving a small amount of headspace that allows for proper carbonation. Finally they cap off the bottles which seals it up and primes it for carbonation.

Carbonating The Beer

Carbonation gives beer its final touch during brewing . During bottle conditioning there happens natural carbonation where by residual yeast ferments added sugar producing carbon dioxide . Forced carbonation on other hand involves injecting carbon dioxide directly into the beer usually done in a keg this methods ensures attainment desired level of carbonation which improves mouthfeel and overall drinking experience through enhancing beers texture .

Common Problems And How To Fix Them

Off Flavors

Causes

Off flavors can spoil your batch completely or impair its quality if not corrected properly during brewing process . Some common causes include poor sanitation , wrong fermentation temperature and storage of ingredients . When agents such as contaminants are introduced into wort they contribute unwanted tastes while high fermenting temperatures lead to esters production alongside fusel alcohols which are harsh on palate too . Ingredients should be stored under cool dry conditions so as to preserve their freshness otherwise old ones will degrade over time thus affecting flavor negatively.

Solutions

Dealing with off-flavors requires close monitoring at every stage of making beer at home . Therefore ensure that you have cleaned all equipment thoroughly before use.Maintain appropriate fermentation temp.Transport materials needed for brewing in well preserved packs where heat cannot reach them easily.Replace outdated yeast with new ones according to recommended pitch rates as failure may cause spoilage.Regularly sanitize your fermenting vessel this helps prevent contamination in addition clean it regularly after use.Consider getting a fridge or any other gadget that can help regulate the temperatures during fermentation.

Starting Fermentation

Stuck Fermentation

Sometimes yeast activity may cease before finishing sugar conversion giving rise to stuck fermentation. This could be due to less pitched yeast cells, lack of enough oxygen and low temperature among others. Yeast health is key in this case because should it fail then everything else will stop working as expected thus leading into off flavors or worse.

Excessive Fermentation

Alternatively there might occur overactive or vigorous fermentation caused by very high temp during such times too much yeast may have been added which leads again into off-flavors alongside excessive foam formation.

Bottling Problems

Flat Beer

Flat beer is not carbonated enough. This problem arises when priming sugar used was little , bottling did not seal properly and insufficient conditioning time . In order for this situation to be avoided one has ensure correct amount of carbonation during brewing process .

Over-Carbonation

On the other hand over-carbonation happens if there was more than required quantity of sugar added for priming , higher than normal temps were experienced at fermentation stage also early bottling could contribute towards over carbonating beer which can be dangerous therefore care must taken during these processes .

A number of steps are involved in the beer brewing process, ranging from malting to bottling. All these steps have an impact on the quality and taste of the finished product. Trying out various ingredients and methods may result in one-of-a-kind, pleasant beers. As such, those who brew beer at home should welcome this adventure and take it as a learning opportunity with every new batch they make. Sharing stories about what we’ve done wrong or right while also asking questions of others who share our passion for making better beer around us can only help improve upon these skills even faster; besides sharing knowledge among peers within any given community will always lead towards gaining more expertise overall too! The art form itself has no limits when it comes down to being creative or finding fulfillment.