Refrigeration in the brewery is essential. Although in the beer brewing process there are many stages where heat exchange occurs – or, in simple terms: heating and cooling wort and beer -, here we will focus on cooling (not heating or cold storage of finished beer).

The main stages where cold is required :

- Post-boil, worth cooling.

- Control of fermentation and maturation temperatures.

Cold is of great importance since, if not controlled correctly, it can lead to serious and irreversible problems in the quality of the beer, that is, unwanted flavors.

Some considerations from thermodynamics :

- The entire volume of the batch must be brought from boiling temperature to fermentation temperature. That’s a lot of energy to remove (more on efficiency later).

- Let us remember that the fermentation process is exothermic, that is, the yeasts generate thermal energy when fermenting. It is for this reason that we talk about cooling and not heating.

From an energy-economic point of view, a good part of the energy costs are also at stake here, usually translated into electrical and water consumption.

WHO IS IN CHARGE OF CARRYING OUT THE COOLING?

In a brewery, the person in charge of controlling the cold is the chiller. A chiller is a machine that removes thermal energy from a fluid or refrigerant, cooling and dissipating heat to the environment. In the case of the brewery, it is typical for the coolant, a water/glycol solution, to consume electrical energy and dissipate heat in the form of hot air to the environment.

This refrigerant circulates through the different factory equipment, cooling where necessary. To carry out this cooling process, each piece of equipment must have a heat exchange system:

- Plate heat exchangers are normally used to cool the wort post-boil.

- To cool fermenting beers, fermentation tanks usually have outer jackets through which the coolant flows.

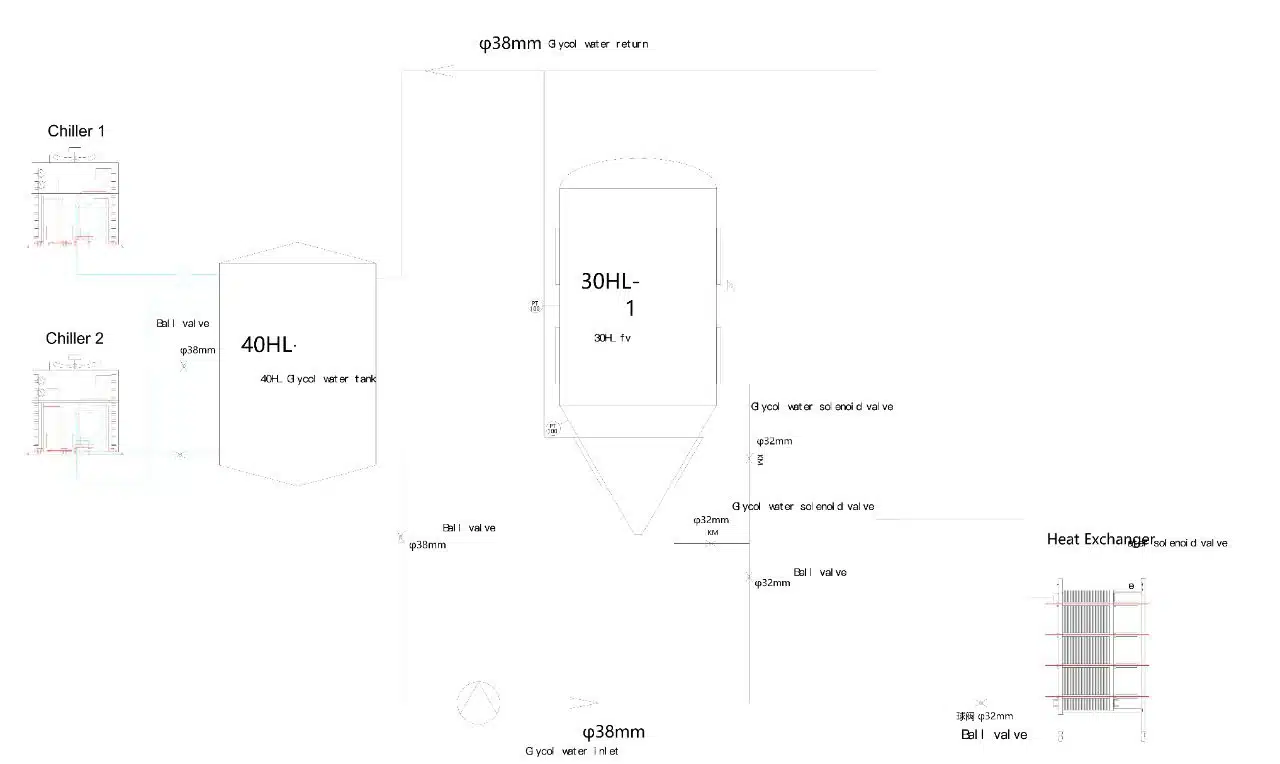

How a typical system is connected

For easy visualization, we will leave a typical diagram of some components of a refrigeration system in a typical factory.

The systems that operate :

- Refrigeration system

- Accumulation ponds

- Heat exchange systems

- Control and automation systems

Its subcomponents :

- Chiller

- Ponds

- Refrigerator

- Pump(s)

- Pipes (piping)

- Electric valves

- control Panel

- Cooling jackets

- Heat exchangers

As can be seen in the previous image, the diagram represents a closed or stationary system, that means that what enters is equal to what leaves (assuming there are no leaks).

A more complete and efficient configuration will require accumulation, recovery and hot/cold transfer systems and tanks.

HOW TO DESIGN AND SIZE

The design must be a system that normally responds to the following considerations :

- Production lot size

- Production recurrence

- Fermentation capacity

- Number of fermentation ponds

- Budget

The above allows sizing the cooling system, where the main factor to consider is the capacity of the chiller and the size of the accumulation tanks.

Before continuing, we will define some items :

- Glycol pond: pond that accumulates glycol. It must be well insulated and have at least one glycol outlet and one inlet. It must have a pump.

- Cold water pond: pond that accumulates cold brewing water. It must be well insulated, have an outlet and a cooling system, such as a coil or jacket. The glycol network is what cools this pond and the cold water is what feeds the plant’s heat exchanger to cool the wort post-boil. It must also have a pump.

- Single-phase heat exchanger: exchanges heat between hot wort and cold water network. It has 2 inputs and 2 outputs.

- 2-phase heat exchanger: exchanges heat between hot wort, process water and glycol. It has 3 inputs and 3 outputs. First it exchanges with process water and then with glycol.

REFRIGERATION FREQUENTLY ASKED QUESTIONS

- Do I include a glycol tank? For 95% of cases we recommend yes.

- Do I include a cold water tank? If the beer production regime is continuous, we suggest yes. The size of the HLT (hot water tank) becomes relevant at this point as well.

- How many chillers should I include? Although a system can perfectly function with only one chiller, having two chillers operating in parallel allows maintenance to be carried out without having to paralyze the plant.

CALCULATION OF CAPACITY OF A SYSTEM

Although the capacity of a system can be calculated, we will leave that calculation hidden so as not to overwhelm with so much mathematics.

For regimen of <1 batch per day :

- Glycol pond: x 2 batch size.

- Cold water pond: Not necessary.

- 2 phase exchanger.

For 1 batch per day regimen :

- Glycol pond: x 2 batch size.

- Cold water pond: x 2 batch size.

- 1 phase exchanger.

For regimen of >1 batch per day :

- Glycol pond: x 3 batch size.

- Cold water pond: x 3 batch size.

- 1 phase exchanger.

Chiller capacity: glycol tank volume/200 (in HP). For example, a plant that has a 2000L glycol tank would need 2 5HP chillers or 1 10HP chiller.