Versatility in Spirits Production

This system does not play favorites. It is built to escort nearly any mash, wash, or pomade from fermentation through two or three columns, collecting the hearts, heads, and tails needed by each style. The outcome—a spirit that carries the wanted nose and mouth feel—looks sharp in glass and on quality-control charts.

High Processing Capacity of 300 Liters

Three hundred liters sits squarely between boutique and industrial, letting a manager run a full day without constant top-offs. Producers gain the comfort of bulk scale without losing hold of the flavor standards that first won customers’ hearts. That mix of volume and craftsmanship rarely appears at the same price point.

Precision and Consistency

Every distillation unit is engineered to lock in exacting control over the heating and vapor path. That tight engineering lets a distiller repeat the same proof, aroma, and clarity batch after batch without chasing the numbers by guesswork. It is the sort of reliability that professionals demand when reputation rides on one trial after another.

Premium Materials for Longevity

Only food-grade stainless steel enters this build, a choice that brushes off corrosion and wipes down in seconds. The alloy will not pit under flaring temperatures or buckle if the spirits are left inside for weeks. Sanitary surfaces paired with rugged construction keep maintenance chores short and product quality high, year after year.

Optimized Heating and Cooling

Responsive heating bodies and coaxial condensers are wired to pull heat exactly when the process calls for it, then shut off with equal speed. That precision stalls runaway temperature spikes and teases out the lighter flavor notes that richer, sloppy runs might scorch. Energy still gets conserved because the system works only as hard as necessary.

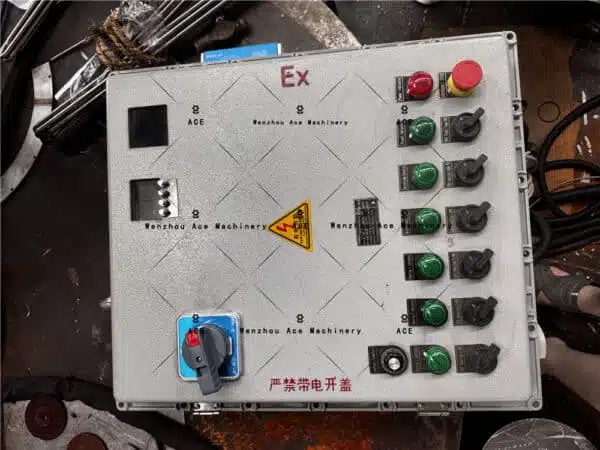

Clear, Intuitive Controls

A single touchscreen panel now replaces arrays of knobs and blinking lights, yet it whispers complexity behind its simplicity. Operators can slide a finger to raise reflux or tap a gauge to watch the ethanol rise—no six-hour orientation needed. That immediacy keeps newcomers confident and veterans focused on crafting rather than fiddling with machinery.

Applications & Real-World Scenarios

Premium Spirits Craft

In the luxury spirits segment, uniformity and craftsmanship come first. The 300-litre setup delivers the polish the best vodka, bourbon or notion makers demand, letting both newcomers and legendary houses stick to their own very high bar.

Customized Liquor Runs

Boutique distillers often crave a kit that bends to whim. This gear indulges that desire by swapping column packing, testing botanicals on the fly, and cranking out once-only gin, rum or specialty liqueurs that catch drinkers’ eyes—and tongues—right away.

Mid-Scale Distilling

Entrepreneurs somewhere between garage and global can breathe again when output hits 8,000 bottles a month. The same 300-litre machine stays nimble enough to coax floral top-notes from wheat yet big enough to push supper-club demand without breaking a sweat.

Technical Specifications

- The still processes up to 300 liters in a single run, accommodating both pilot projects and larger craft batches.

- Crafted from high-grade stainless steel, the kettle resists corrosion and cleans easily between uses.

- Choose between electric heating coils or a steam-jacketed system, depending on your facility’s fuel availability.

- Digital controllers manage both heat and cool zones with 1°C accuracy, locking in desired temperatures during every phase.

- Design supports traditional pot distillation and modern continuous columns, offering producers maximum versatility.

- An integrated water-cooled condenser eliminates the need for external chillers and allows quick product recovery.

- Producers can ferment grains for whiskey, fruit for brandy, or botanicals for gin on the same unit with minimal configuration.

- The still plugs into standard three-phase industrial power, streamlining installation in most distilleries.

How It Works

Ferment your chosen substrate grains, fruits, or waste stream until yeast converts sugars into a low-wine mash.

Transfer the wash to the column, where the heating system vaporizes alcohol while leaving heavier compounds behind.

The vapor travels to the condenser, cools rapidly, and emerges as liquid spirit for collection.

Distillers monitor the head, heart, and tail cuts via temperature and time, scrubbing unwanted fuels and capturing key flavor compounds.

The finished product can be racked into barrels for aging or bottled immediately, ready to reach consumers.

Commonly Asked Questions (FAQs)

What types of spirits can I produce with this equipment?

This setup can turn out everything from light vodka and aromatic gin to heavier offerings like whiskey, rum, and even fruit-forward brandy or specialty pine-nut liqueur.

How do I maintain the distillation equipment?

A quick rinse with water plus a mild, non-corrosive detergent does the trick; the stainless-steel body stands up to regular use and cleans up nicely.

Is this distillation system suitable for small or boutique distilleries?

Certainly. The 300-liter capacity fits comfortably within the toolkit of medium-scale craft producers who need to chase quality in limited runs.

What is the heating source for this distillation equipment?

You can fire it with electric elements or hook it up to a steam line, so you pick the heating method that makes sense for your bottom line.

How long does the distillation process take?

Cycle times shift with the spirit recipe, but a complete run generally spans a few hours, adjustable to match whatever pace your plant is running.

Conclusion

First-rate distilling machinery serves as the bedrock for any operation aiming to turn out spirits of elevated quality and reliability. Our flagship 300-liter column allows producers to enlarge their output without sacrificing the attention to detail that great products demand. If you’re prepared to advance your workflow, reach out at your convenience and begin the upgrade that will redefine your brand.