Key Advantages:

- Lifting Ears: All tanks are constructed with lifting ears to facilitate lifting the tank during installation.

- Flexible Beer Delivery: A rotating elbow and racking arm combine to allow convenient and flexible beer transfer.

- Precision Engineering: A guard plate of elliptical shape is installed between the pipes when the legs are joined with the lower cone and the refrigerant inlet pipe.

- Adjustable Leveling: Adjustable bolts are supplied to maintain the favorable angular disposition of the fermenter.

- Rotatable Clamp: There are two clamps, one at the material port and the other at the bottom of the tank, both of which rotate without restriction.

- Aesthetic and Durable: The bright tank features a cladded bottom to give it a neat finish and make it strong.

- Integration of CO2: Comes with a carbon stone for proper CO2 infusion in all bright tanks.

- Easy Maintenance: The shadowless manway style enables thorough cleaning, along with an adaptable top manhole for different brewing processes.

- Sufficient Headspace: Designed with extra headspace to ensure the volume does not include the top head, optimizing fermentation.

- Efficient Cooling: Cooling jackets are installed on both the top cone cylinder and bottom cylinder, providing a very large surface area for cooling.

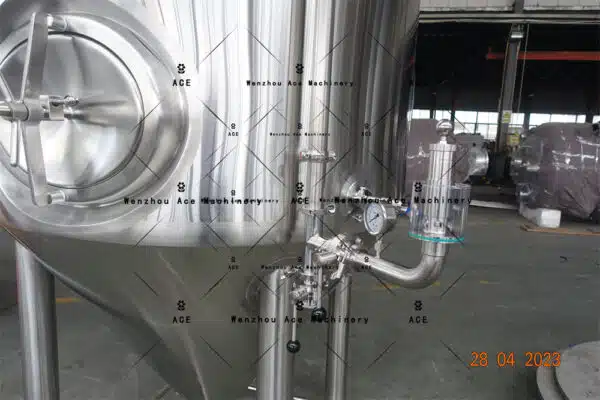

- Safety Features: Includes safety devices such as positive and negative pressure reliefs.

- Appropriate Yeast Excretion: The 60-degree cone angle is ideal for proper yeast discharge.

- Convenient Operation: An access ladder is built into the machine for easy climbing and operation.

Standard Configuration:

- Produced from food-safe 304/316 stainless steel.

- Constructed with a double wall dimple cooling jacket.

- Inner surface ground to a 2B finish and passivated.

- Oversized to enable a 25% headroom during the fermentation process.

- Includes a sanitary tri-clamp sampling valve.

- Features a mansard manhole or access door at the top.

- Equipped with a sensor and PT100 thermowell.

- Includes a rotating racking arm in the conical bottom.

- Available with a 4/6 inch dry hops addition port.

- CIP spraying ball covers 360 degrees.

- Cooling water threaded inlet and outlet.

- Pressure relief valve with gauge.

- Lifting bar provided at the top edge of the tank.

- Assembled with heavy-duty legs featuring sliding-type bolts.

- Safety valve located on top of the tank.

- 60-degree slope for the outlet to dump the yeast.

Optional Configuration:

- Temperature display.

- Biggest blow-off designed and CIP plumbing extent.

- Carbonation stone for the dissolution of gases into liquids.

- Liquid level measurement from the sidewall.

- Capping Tool/Spunding Valve.

Specifications:

- Capacity: Design volume 7 BBL, working volume 8.75 BBL

- Nominal Capacity: 8.75 BBL S.G. 1.2

- Outer Dimensions: 1160*2500mm

- Material: SUS304/SUS316 Stainless Steel

- Control System: Siemens PLC or Schneider PID or ABB PID

- Cooling Area: 8.75 Square meters

- Surface Finishing: Pub polished, brushed satin finish, mirror, or pickling passivation

- Pressure Rating: Inner Jacket 0.4 MPa, Heating/Cooling jacket 0.5 MPa

- Rated Pressure: Inner Jacket 0.2 MPa, Heating/Cooling jacket 0.3 MPa