Maintaining and prolonging the lifespan of equipment require routine CIP cleaning, to avoid corrosion or blockages that would require costly repairs later. CIP cleaning ensures peak performance by clearing away accumulation or residue that might contribute to malfunctions and costly repairs later.

Sanitation and Food Safety

In the food and beverage industry, sanitation and food safety are of the utmost importance. Equipment that has not been thoroughly cleansed may become contaminated and house harmful microorganisms; CIP cleaning provides an efficient method to rid equipment from potential pollutants while guaranteeing its safety for use.

Efficiency and Cost Savings

Clean In Place (CIP) cleaning is an efficient and economical method of equipment sanitation and can save both time and labor expenses by doing away with manual disassembly processes. Furthermore, CIP can also be completed quickly to enable more frequent cleaning cycles without interfering with output; long term, this may provide significant cost savings due to reduced equipment maintenance expenses or failure costs.

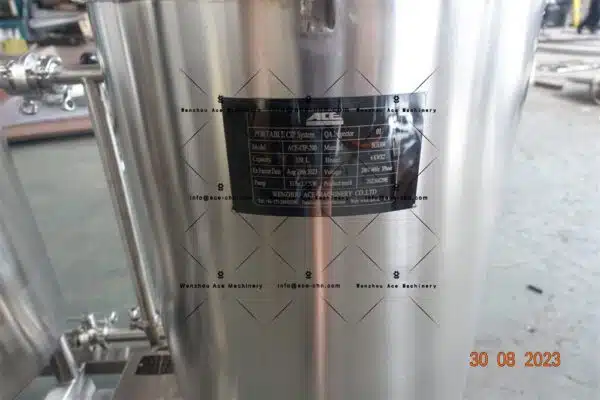

CIP clean in place Parameters

- Capacity: 50L~1000L

- Material: SS304/316

- Vessels: 1/2/3/combi/multi, customized

- Heating way: electric/steam

- Automation: manual/automatic

- Suitable for: microbrewery, winery, cidery, other beverage/edible oil stainless tanks cleaning

- Customize: available, we can design/manufacture according to clients’ operation needs

CIP System Advantages:

- It can make the production plan reasonable and improve the produce ability.

- To compare with the hand-wash, it doesn’t influence the cleaning result because of the worker’s difference, on the contrary, it can improve the products’quality.

- It can prevent the dangers of cleaning work, so that we can save the work force.

- It can save the cleanser, the steam, the water and the cost of production.

- It can extend the service life of the machine parts.

- It includes three types, one is the handwork system, one is the semi-automation system, and the other is the whole automation system, so it is easy for customer’s selection