Key Features & Specifications

Optimal Heat-Up and Operating Time Period

- Faster Heating Times: One Hour Heat Up helps in reaching the boiling point quickly for effective distillation.

- A 4-5 Hour Stripping Run ensures that all unwanted contaminants are removed in a short period.

- A complete work cycle ranges between five and six hours for distillation, achievable within a single working day.

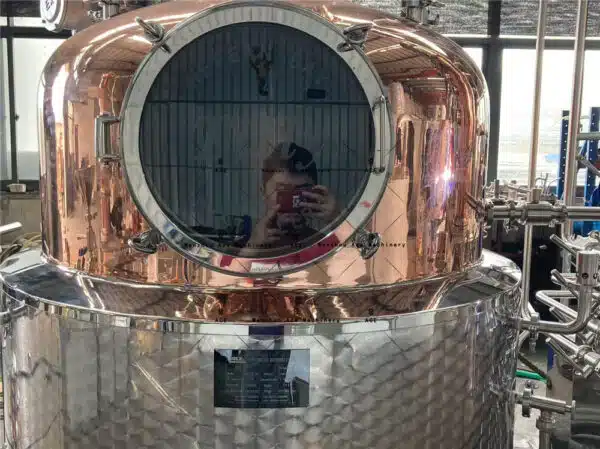

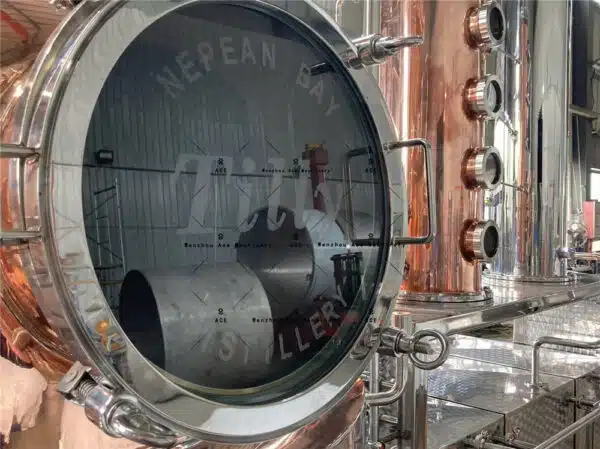

Unparalleled Construction Quality

- Still-pot: Reliable warm and red copper or strong SS304 stainless steel, designed for exceptional durability.

- Gooseneck (Helmet): Clear distillation thanks to high vapor flow management and condensation, provided by the red copper gooseneck.

- Gin basket: This red copper, glass, or SS304 stainless steel basket is ideal for botanicals during gin distillation, enhancing flavor and aroma.

- Distillation Column: Red copper column with 4–12 plates, allowing high purification and alcohol volume control for spirit distillation.

- Dephlegmator: Built with red copper or SS304 stainless steel, it pre-condenses vapors that rise.

- Condenser: Crafted from red copper or stainless steel, allowing vapor cooling to produce smooth, high-quality spirits.

- Parrot Outlet: SS304 stainless steel parrot provides easy and efficient distillate alcohol content measurement.

- Support Structure: Sturdy SS304 support ensures equipment stability and safety.

Customizable Features

- High Torque Mash Agitator: Safe stirring across all models with CE/UL/CSA/ATEX Explosion Proof specifications.

- Voltage Flexibility: Operates across a range of voltages (110V-600V) with either 1 or 3 phase, 50 or 60 Hz.

- Material Selection: Choose between stainless steel or copper for key components like the pot, condenser, and dephlegmator.

- CIP Pump and Pipe: Clean in Place reduces waste and allows easy cleaning without disassembly.

- Spirit Collection Tank: Collects head, heart, and tail portions separately for quality enhancement.

An Overview of the System’s Performance

Top Use Cases

Ideal for producing spirits like gin, rum, whiskey, and brandy, offering versatility for distillers.

Alcohol Content After Distillation

Achieves an alcohol content of 70-85%, based on the configuration and distillation process.

Versatile and Cost-Effective

The system’s structure and flexibility are beneficial for new distilleries or for increasing production capacity.

Easy Maintenance

Red copper and SS304 stainless steel components are corrosion-resistant and feature Clean in Place (CIP) capability for minimal maintenance.

Reasons Why Your Equipment Should Be Built with Copper and Stainless Steel

Using red copper and 304 stainless steel in our whiskey distilling equipment lessens contamination risk and enhances aesthetic appeal. Copper elements, like the gooseneck and distillation column, help sulfate ions blend in and eliminate unwanted flavors, enriching the spirit’s flavor.

Customizability Options

We offer custom designs to meet the unique needs of each distillery. Customization includes:

- Component Material: Select copper or stainless steel for key components based on your requirements.

- Distillation Column Plates: Adjust the number of plates to achieve the desired alcohol content.

- Voltage & Power Configurations: Flexible power configurations for regional compliance.

- Explosion-Proof Certificates: Enhance safety when handling explosive materials and high-proof spirits.

Take a Look at Our Equipment for Commercial Liquor Distillation

This system is designed for efficient distillation, widespread use across various spirits, durability, and easy maintenance with Clean in Place capabilities.

FAQs – Frequently Asked Questions

Can this equipment be used for both finishing and stripping runs?

A: Yes, our distillation system is versatile for both stripping and finishing runs, supporting multiple spirits production.

What will be the alcohol content after distillation?

A: Alcohol content ranges from 70 to 85%, depending on column configuration and technique.

Are custom designs offered?

A: Yes! We provide options like material choices, column plates, and voltage specifications for custom setups.

What benefits do copper parts provide?

A: Copper removes sulfurous substances, enhancing the taste of finished spirits.

What power configurations can be applied for this equipment?

A: Operates at multiple voltages (110V-600V) and offers three-phase 50/60Hz frequency options.

How often does the system require cleaning?

A: Cleaning is easy with the CIP system; we recommend after each production cycle for optimal performance.

Can I request additional parts, like a non-exploding agitator?

A: Yes, optional equipment like explosion-proof high-torque agitators is available for enhanced functionality and safety.

All our commercial liquor distillation equipment ensures efficiency, versatility, and quality in a single package. Our innovative designs and high-quality craftsmanship are ideal whether starting a new business or modernizing your distillery.