Main Features

High-efficiency filtration: Plate and Frame Filter Press adopts high-pressure filtration technology, which can quickly separate solids and liquids in the mixture and significantly improve the filtration efficiency.

Compact structure: the equipment has a compact design and small footprint, suitable for various production environments.

Sturdy and durable: the filter plate and frame are made of high-strength materials, corrosion-resistant, high temperature-resistant and with long service life.

Simple operation: the equipment is equipped with automatic control system, which is easy to operate and maintain, and reduces the cost of manual operation.

Multipurpose design: according to different material characteristics and process requirements, the equipment can be flexibly configured with different types of filter cloth and filter plate to meet a variety of filtration requirements.

Technical Parameters

- Filter area: 10-500 m²

- Filter plate size: 320×320 mm to 2000×2000 mm

- Working pressure: 0.6-1.6 MPA

- Chamber volume: 0.1-20 m³

- Motor power: 1.5-11 kW

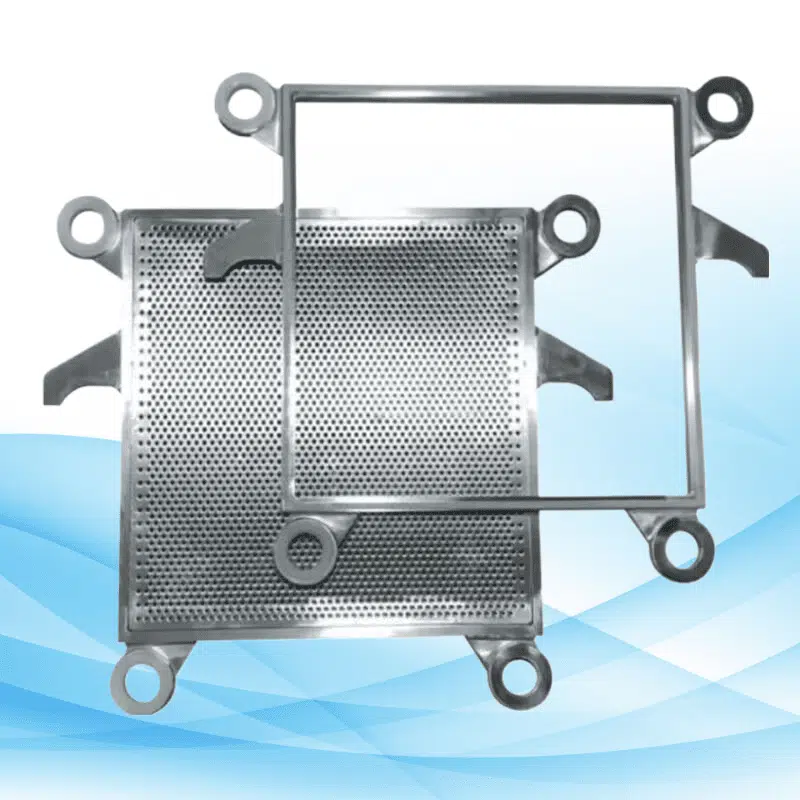

Components of a Plate Filter

A plate filter’s main components include its frame, plates, filter cloth and hydraulic closing mechanism. The frame supports and maintains pressure on each of these elements, while the hydraulic system securely closes them during filtration processes.

High Separation Rate

Due to their superior separation rate, plate filters are ideal for applications requiring thorough solid-liquid separation.

Improved Product Quality

Plate filters play a direct role in improving the final quality of the end product. By producing a drier cake through their filtration process, plate filters ensure impurities are reduced drastically – particularly important in industries such as wine and beer processing.

Customizable for Every Application

Their size and number of plates can be altered to accommodate varying volumes of liquid, while various fabrics of filter cloth may be employed depending on what types of solids need filtering.

Contact us to order info@ace-chn.com +86 18626835909