Key Features:

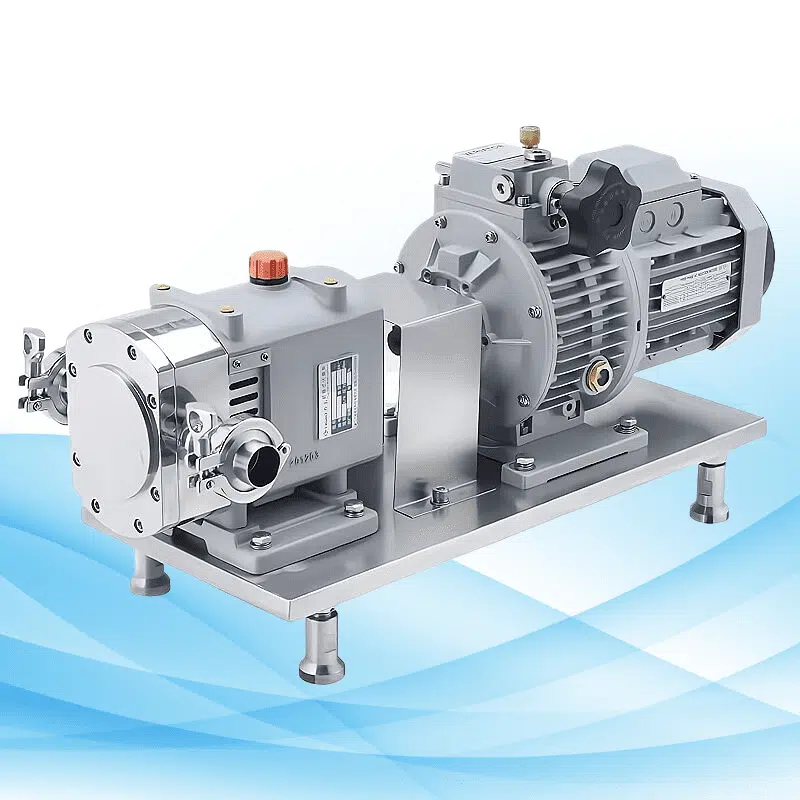

Attractive Pump

With its cutting-edge motor system, this pump ensures steady and constant liquid transfer at fast and consistent rates. It delivers constant flow and pressure for optimal liquid transfer performance.

Versatile Application

Perfect for operations of all sizes – from home breweries to large commercial wineries -, this conveyor can easily meet the transfer needs for different batches and volumes. Plus, its superior protection ensures smooth sailing.

Gentle Handling

Low shear design can effectively minimize oxidation and mechanical damage to wine, maintaining its purity in flavor and high quality.

Hygienic design

Crafted with food-grade materials, this pump’s body is smooth and free from dead spaces, making cleaning effortless and meeting hygienic standards to prevent contamination. User-friendly

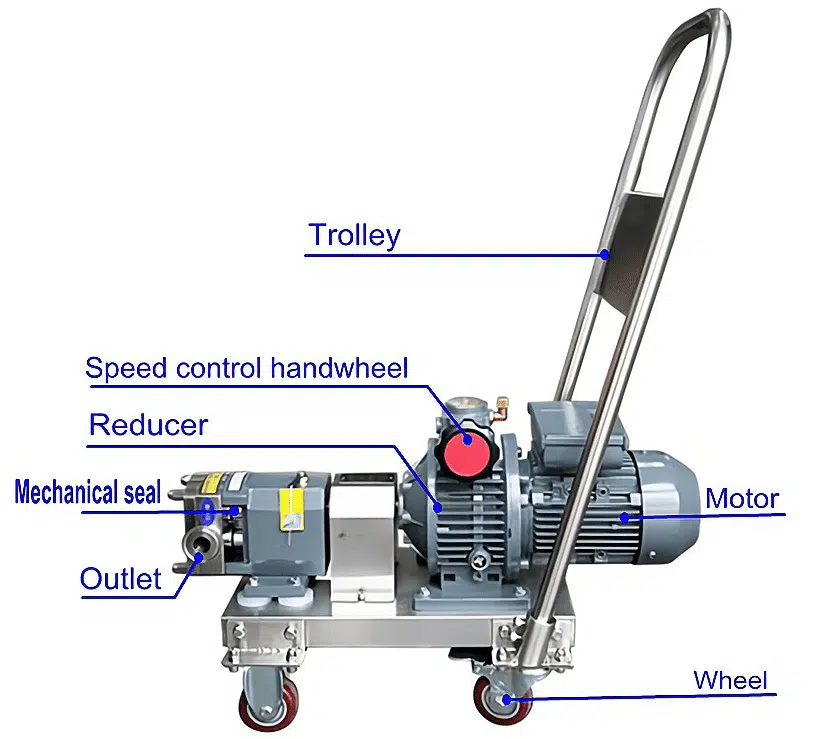

Portable Design

Conceived as an easily transportable unit, with compact dimensions and lightweight materials for portability in wine cellars or breweries. An optional handle allows free movement.

Durable and Reliable

- Rugged Construction: Utilizing high quality stainless steel and corrosion-resistant materials guarantees long-term service life in humid or acidic environments.

- Low Maintenance: Advanced sealing technology and precision components reduce wear and leakage, cutting maintenance costs and frequency significantly.

Technical Specifications:

- Technical specifications:

- Voltage: 220V / 380V

- Power: 0.75kW / 1.5kW / 2.2kW

- Flow rate: 300 L/h – 3000 L/h (depending on model)

- Maximum pressure: 4 bar

- Material: stainless steel 304 / 316

- Weight: 80kg – 200kg (depending on model)

- Dimensions: customized according to model

How to Use Our Wine Transfer Pump

Using a wine transfer pump may seem daunting at first, but it’s actually a relatively simple process. Here is a step-by-step guide on how to use a wine transfer pump:

Step 1: Prepare the pump

Before use, make sure the pump is clean and free of any contaminants. If necessary, disassemble the pump and clean each part separately with warm water and a mild detergent. After cleaning, reassemble the pump.

Step 2: Connecting the Pump to the Wine Dispenser

Follow our instructions for connecting the pump to the container. Make sure all connections are secure to avoid any leaks during transfer.

Step 3: Begin Transfer

Once the pump is connected, turn it on and let it run for a few seconds to remove any air from the system. You should see the wine begin to flow through the pump and into the dispenser.

Step 4: Monitor the transfer

During the transfer process, it is important to monitor the flow rate to ensure it meets your needs. If necessary, adjust the pump speed to increase or decrease the flow rate.

Step 5: Finish Transferring

When transfer is complete, turn off the pump and disconnect it from the wine dispenser. Be sure to clean the pump thoroughly after each use to prevent contaminant buildup.

Applications:

- Wine Making: For the transfer, mixing, filling and bottling of grape juice and wine.

- Fruit Wine Production: Used for various fruit wine production processes.

- Other Food & Beverages: Also utilized for transporting liquids such as beer, fruit juice or milk etc.

Add precision and sophistication to your winemaking process with the Wine Transfer Pump from us today – contact us for product info or ordering info!