The first step to making perfectly distilled spirits begins with proper selection of distilling equipment. If you are a hobbyist or a professional distiller, knowledge of the various distilling equipment lets you use better technique and improves the overall efficiency of the distillation. This guide examines the structure and function of the equipment with examples such as pot stills, column stills, among others, guiding you to what is ideal for you.

Grasping Distilling Equipment

Distillation equipment is essential for separating alcohol from fermented sugar syrup, a process that has been refined over the centuries. It has been recognized that the design of distillation equipment is crucial not only to the effectiveness of the distillation process, but also to the taste and quality of the finished product. Let us introduce you to the main types of distillation equipment you wish to know about, and we hope you have every success in your search for new distillation equipment.

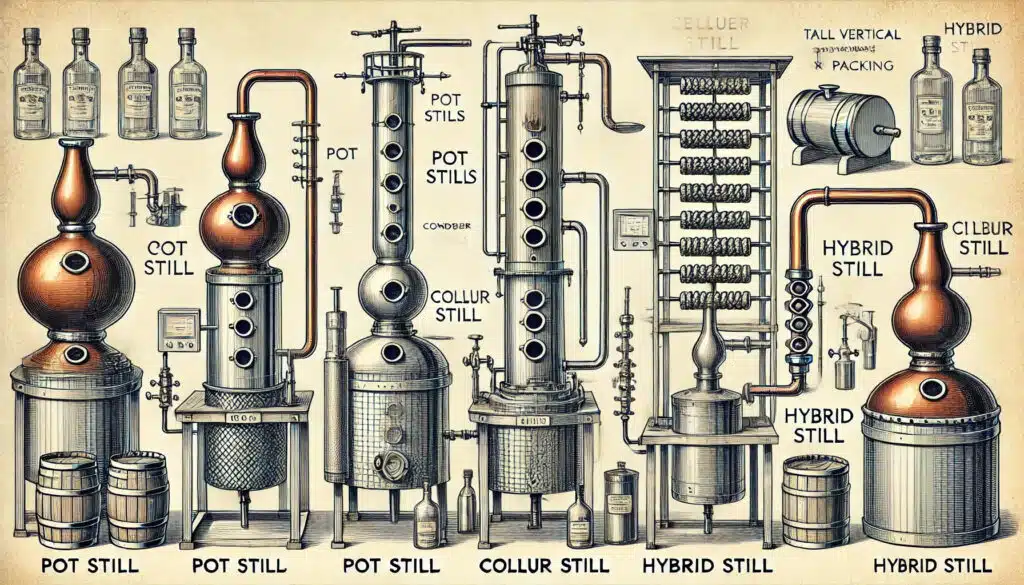

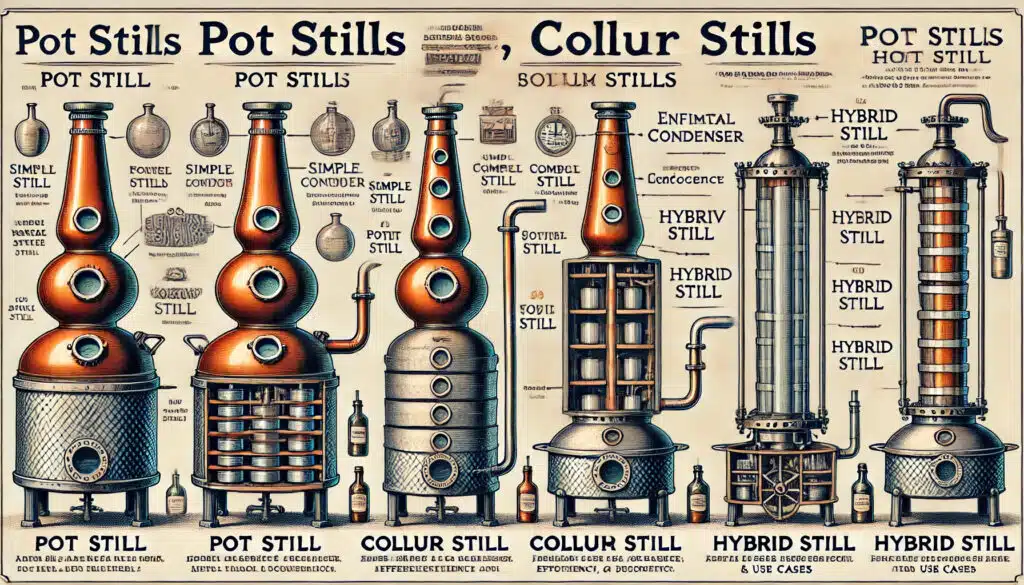

Kinds of Distilling Apparatus

1. Pot Stills

Pot stills are the simplest types of distilling equipment that is quite old. Apparatuses generally require only two main components, and they are a pot (or boiler) and a condenser. Inside the working pot, the fermented mash is being heated up and the entrained water vapor will disperse. The vapor is then cooled down and changed back into the liquid state in a condenser. An advantage of using pot stills is the preserving of the flavor. Pot stills are appreciated in the manufacture of heavy drinks like whiskey and rum, as they absorb the flavor of the raw materials. Thanks to their uncomplicated construction, a pot still offers ease of use, even to the novice distiller. However, sore disadvantages can be expressed as follows: Low Efficiency Advantage. Mostly, compared to column stills and head stills, pot stills have relatively low alcohol yield and several distillation runs have to be carried out for strong spirits.

2. Column Stills

Column stills, otherwise called continuous stills, you will appreciate that these are more advanced forms of pot stills and therefore economize the distillation-drying process. They are made of compound vertical columns that have blanket trays or packing materials. As inclusive of the fermented mash on the upper part of the column, it is expected to go down as vapor goes up at the bottom. Advantages: Higher Efficiency: In a single distilling process, the amount of alcohol which can be produced is higher in the column stills as compared to other stills, making them suitable for mass production. Versatility: These can be modified to yield different styles of spirits, from very light types such as vodka to very dense ones like rum. Disadvantages: Cost: Most often people would point out that column stills are on the expensive side, or they require more costs in terms of installations and maintenance. Flavor Dilution: The distillation process is efficient but at the expense of some flavor characteristics.

3. Hybrid Stills

Hybrid stills are a blend of pot and column stills, thereby providing flexibility to the distillers. These devices enable batch mode as well as continuous mode of distillation, thus they are relevant to a number of spirits. Advantages: Flexibility: Distillers may utilize pot or column distillation process to match the demands and hence embrace the creativity. Balanced Output: They are able to strike a decent trade-off between retention of flavor and alcoholic output. Disadvantages: Complexity: Operational and maintenance concerns of the design tend to be relatively more complex, involving a steep level of skill.

Choosing the Right Equipment for Your Needs

During the process of planning to purchase distilling equipment, the following should be considered:

- Scale of Production: Are you distilling for personal consumption or for sale? For small batch processing, a pot still may be adequate. However, if you are forecasted to expand, you may invent any type of column still or hybrid still.

- Desired Spirits: What kind of spirits do you intend to manufacture? Pot stills are preferred for those who wish to create spirits rich in flavors for instance whiskey, conversely high proof spirits like vodka are better placed in column stills.

- Budget: Budget shall however govern your choice of distilling equipment. Pot stills are less expensive, however for production on a larger scale a column still would be more prudent in the long term.

Additional Considerations

Safety as a Precaution: When preparing for distilling activity, safety should always come first. When setting up, do not violate the local safety codes and requirements. Avoiding risks in the distillation process is easy with proper ventilation, temperature control and also monitoring. Development of the spirit is definitely affected by the materials found in a person’s distilling equipment, as such devices will have a direct correlation with the quality of the spirit. Stainless steel is one of the most commonly used materials due to high resistance to corrosion and its long-lasting features. However, copper is a great asset as it helps in removing unwanted sulfides which would otherwise make the liquor to be poor. Maintenance is one of those situations where dedication and attention must be ordered in a context which guarantees proper order of the equipment and tools used in distilling. This entails proper cleaning, checking of potential fluids leaking, and monitoring assorted parts for any destruction as well. If a certain still is well taken care of, it is poised to work at an optimum level and yield more quality spirits than before.

Conclusion

Define equipment to be one of the essential steps towards successful completion of the whole distillation process. Knowing the various types of distilling equipment—pot stills, column stills and hybrids—will enable you to make the most appropriate decision that meets your target. By all means, be prepared for the greatest adventure in the process of distillation but do not forget about such ideas as, what kinds of spirits you want to produce, scale of production, how much can you afford and safety restrictions. With such conditions, it will only be a matter of time before beautiful spirits made in your style will be in your hands. In such a way, it can be said that the achievement of the desired quality of liquor is possible only by use of the appropriate pieces of equipment. Delve into the art of distillation, and allow every drop in each bottle that you create to be encompassed with sheer artistry.