Understanding Column Stills: An Introduction

Let’s start at the basics. A column still, also referred to as a continuous still, is an apparatus designed for distillation purposes.

Distillation is used to separate alcohol from fermented mixtures using continuous distillation.

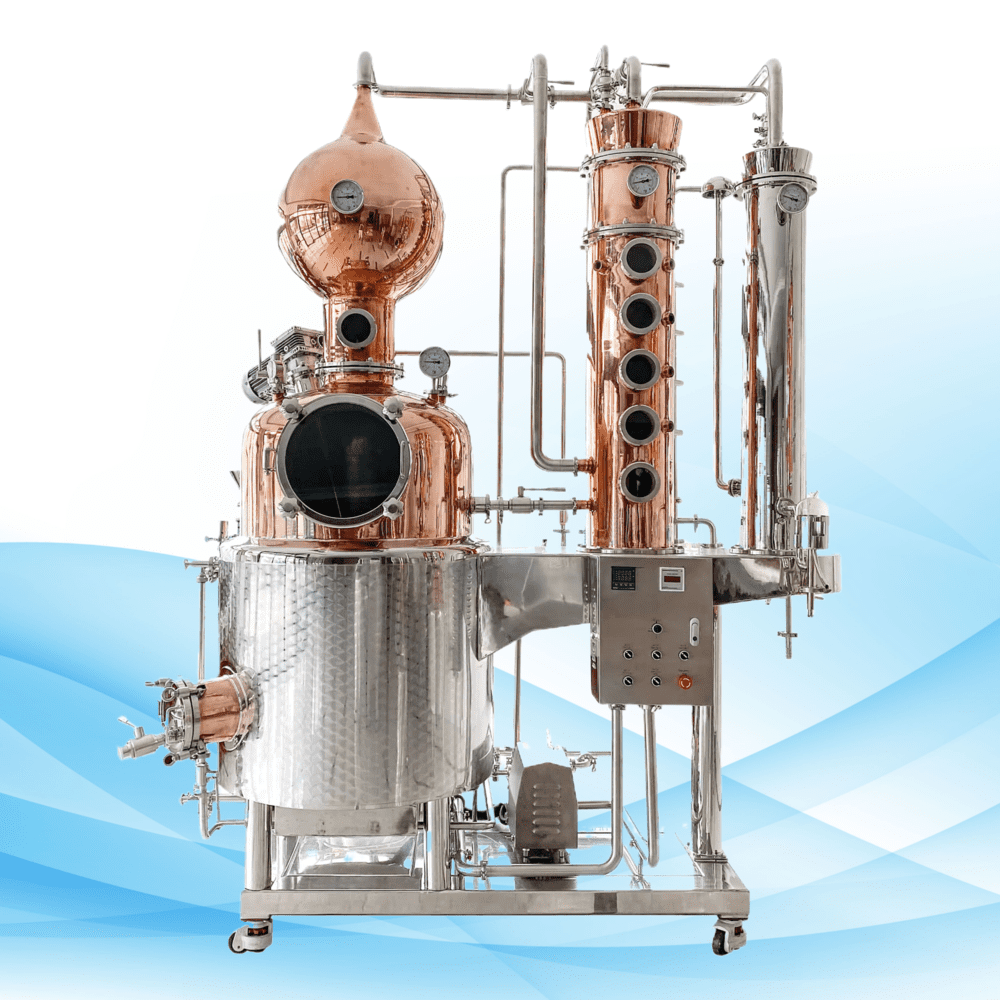

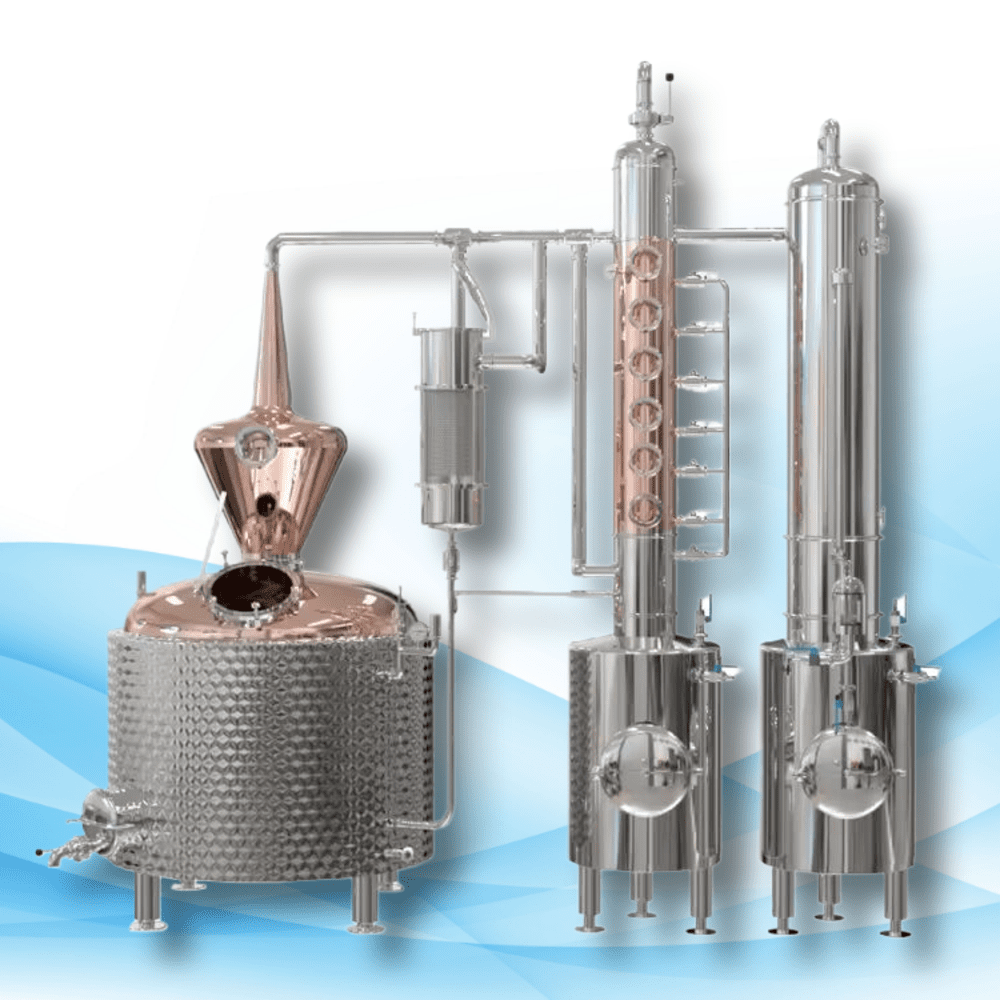

Column stills consist of four primary elements, such as the boiler, column, condenser and collection vessel. The boiler heats the fermented mixture to produce alcohol vapor, while its column heats it and collects its produced alcohol vapor into a collection vessel for collection.

Vapor ascends a column filled with plates or trays and interacts with these surfaces as it rises, condensing and then re-vaporizing multiple times along its journey.

Reflux purifies alcohol; the more times that its vapor passes through this process, the purer the liquor becomes.

After being purified, purified alcohol vapor is sent through to a condenser where it will be cooled and condensed back into liquid state – this “high proof spirit” then being collected into its collection vessel for final collection.

Column stills provide us with an essential method of distillation; but their operation goes much deeper, as we shall see in subsequent chapters.

History and Development of Column Stills

Column stills have an intriguing past that dates back to their creation by an Irishman named Aeneas Coffey during the early 19th century.

Coffey was an excise tax collector. Utilizing his expertise of distillation to improve upon existing pot still designs and invent the Coffey still, which revolutionized spirits production worldwide.

Coffey stills provided continuous distillation – an innovation which enabled distillers to produce spirits on an industrial scale with higher alcohol contents than before.

Over time, column still designs have evolved rapidly to become more efficient and simple to operate, producing spirits such as bourbon or vodka with ease.

Column Still vs. Pot Still: What’s the Difference?

Distillation stills can generally be divided into two broad categories, column stills and pot stills, although what differentiates these stills may depend on your requirements and industry needs. Here we explore their distinctions.

Pot stills are among the oldest type of still. Operating under batch distillation principles, they distill fixed amounts of liquid at one time before emptying out and refilling for subsequent batches of distillation. Once this batch of liquid distillation has concluded, pot stills should be emptied out to make space for its next use.

Column stills use an uninterrupted distillation process to operate more efficiently and produce greater quantities of spirits. They run nonstop and distill liquid as it enters their system, producing large volumes at one time. This makes column stills more cost-effective as well.

Pot stills produce spirits with lower alcohol concentration and more flavor due to retaining more of their original characteristics from mash fermentation.

Column stills offer another solution for creating high-proof spirits by more effectively isolating alcohol from mash, yielding purer spirits without as many flavors from their original source.

At the core, your decision between pot and column stills ultimately comes down to what results you desire from them. For spirits with rich, complex flavors such as cognac or port, pot stills might be your preferred method; otherwise, for high proof pure spirit production column stills may provide superior results.

Anatomy of a Column Still (Continuous Still)

Column stills (also referred to as continuous stills) can seem intimidating at first, but once you understand their parts and their functions they become quite fascinating machines.

Let’s begin at the base with the boiler, where water-soaked fermented grains (mash) is heated until all alcohol within has vaporized; since alcohol has a lower boiling point than water.

Vapor then ascends through a column filled with plates or trays equipped with small holes designed to let vapor through and pass into its path, where it cools off before condensing on them as it rises higher up the column.

At the top of each column is a condenser, where vapor is further cooled until it fully condenses to form high-proof spirit that is collected into vessels for storage.

At last comes the rectification section. Here the heads, hearts and tails are divided up; any harmful substances found will be removed prior to separation; hearts contain pure spirit content while tails sometimes contain strong flavors that should either be removed altogether or redistilled before discard.

Now you understand how a column still works; its intricate inner workings turn mash into delectable spirits that you’d enjoy sipping!

How Column Stills Work: Distillation Simplified

Column stills are amazing pieces of equipment. Not only are they essential in distillation processes, but there’s so much science involved!

Step one of this process entails heating mash in a boiler. This heat causes alcohol contained within it to vaporize due to its lower boiling point than water; this vapor then rises into a column for further processing.

Inside the column, the rising vapor meets with plates or trays which are cooler than its source; this causes some of the rising vapor to condense on these cooler surfaces; but once again heat from rising vapor can re-vaporize this condensed liquid again!

Reflux, the cycle of vaporizing and condensing, is an integral component of distillation. As more cycles pass through this cycle, more alcohol will be extracted from its component parts in the mash.

Once the vapor reaches the top of a column, it moves to a condenser where it’s further cooled until fully condensing into liquid form and collected in a vessel as high-proof spirit.

But the process doesn’t stop there: once the liquid has been fermented and refined, it undergoes a rectification step in which the heads, hearts and tails of spirit are separated from one another based on harmful substances found therein; hearts contain only pure parts while tails contain strong flavors often too strong for distilling; these latter ones must then either be discarded or redistilled as necessary.

At its heart, distillation in a column still is an intricate dance of heat, cooling and reflux; and its result? A delicious high-proof spirit.

The Role of Column Stills in Bourbon Production

Column Stills in Bourbon Production, Column stills play an essential part in producing bourbon; they act as workhorses of the industry by contributing to its unique flavor profile.

Bourbon must adhere to stringent legal regulations, one of which dictates its distillation at no more than 160 proof. Column stills are an ideal way of distilling to this limit as they allow distillers to easily adjust proof levels via boiler heat adjustment or by increasing or decreasing plates in their column stills.

Bourbon must also contain at least 51% corn. Here, the column still plays an essential part; its ability to handle high sugar contents without getting clogged is an advantage over pot stills which often struggle with thick mashes is considerable.

Next time you pour yourself a glass of bourbon, take a moment to appreciate its production in an open column still.

Column Still and Reflux Still Comparison

Distillation requires different still types, two of the more prevalent being column stills and reflux stills. But what exactly are their respective differences?

At first glance, column stills and reflux stills may look similar: both have tall columns equipped with boilers at their bases and condensers up top, yet their operations vary considerably.

Column stills (also referred to as continuous stills) are designed for continuous operation; their design allows mash to continuously enter their boiler while distillate is collected at the top, making these machines highly efficient and ideal for large-scale production.

Reflux stills operate differently: each batch of mash is loaded into the boiler before running the still until all alcohol has been extracted; once completed, emptying, cleaning, and refilling begin the process again – making them more labor-intensive than their counterparts but producing very high proof spirits.

Key differences include how each method controls reflux; in a column still, this can be controlled through its number of plates in the column whereas, for reflux stills, reflux control can be adjusted via an adjustable reflux condenser at the top of their column allowing more control during distillation process and ultimately more of an influence over final product quality.

Column and reflux stills have similar features; however, each differs significantly in key ways that could influence which still is best suited for your distillation needs. Being aware of these distinctions will assist in selecting an apt still to meet these objectives.

The Impact of Column Still Design on Flavor

A column still’s design can have an enormous effect on its final flavor profile, as its layout determines how vapors interact with and condense inside of it.

Height can have an influence over the purity of spirit; taller columns provide more surface area for the vapors to interact with and thus achieve higher purification levels, producing lighter, cleaner flavors in spirit products.

Still materials also play a crucial role in shaping flavor profiles. Copper stills are commonly used and their copper components react with the vapours to remove impurities that might create off-flavors for smoother spirits and refined spirit.

A number of plates or trays in a column also plays a significant role. Each plate acts like mini-distilleries to further refine and perfect spirit; more plates could lead to more refinement resulting in a more neutral spirit; on the contrary, having less plates may produce something with greater character or flavor.

Design of a column still can have a dramatic effect on the flavor profile of its spirits produced, and distillers should understand how various design features affect distillation processes in order to fine-tune their stills for maximum flavor. By understanding which design features are responsible, distillers can tweak their stills according to individual flavors that they wish to achieve.

Column Stills in Action: From Craft Distilleries to Bourbon Giants

Column stills aren’t only used by large distilleries for crafting high-quality spirits – craft distilleries also rely heavily on them when creating unique spirits with distinct flavor profiles.

Jim Beam and Maker’s Mark distilleries employ large column stills for their operations, often several stories high, to produce thousands of gallons daily of spirit. However, regardless of this massive scale these distilleries strive for consistency when it comes to flavor and quality control.

Column stills can also be utilized in the production of other spirits such as rum and vodka, including many Caribbean distilleries that use column stills to craft light yet clean rums, while vodka producers frequently utilize column stills in order to attain high purity standards required by this spirit.

From small craft distilleries producing just a few hundred bottles each year to giant distilleries producing thousands of gallons daily, column stills are indispensable tools that play an integral part in crafting spirits we enjoy today.

Conclusion:

Column stills play more than an instrumental role in spirit production – they form the backbone and shape the character, flavor and quality of spirits we enjoy every day.

Column stills have become the backbone of distilling for global spirits giants as well as craft distilleries around the world – shaping new trends and innovations with each passing year, but one thing remains certain – distillation would not exist as an art or science without this humble column still!