What Is Malt

Malt is an integral component in many popular food and beverage products, such as beer, whiskey, malted milk balls and bars.

But exactly what is it, and how is it used in these items?

In this article we’ll examine its history, uses, brewing process role and role in distillation.

History of Malt

Malt has an expansive history in food and beverage production that dates back centuries, from ancient civilizations like Egypt, Greece and Rome all using malt for bread-making purposes to its use in medieval Europe’s ale drink production process until hops were added as early as 16th Century giving way to what we recognize today as modern beer beverages.

Types of Malt

There are various kinds of malt available, each offering specific advantages.

Some common varieties include:

- Base Malt: Base malt is the foundation for most beers. It provides most of the fermentable sugars needed to produce beer, while adding color and flavor.

- Specialty Malts: Specialty malts are used in smaller amounts to add certain flavors and hues to beer, from light toasting to heavy roasting, adding notes such as caramel, chocolate or

- Roasted Malt: Roasted malts are used extensively in dark beers like stouts and porters, giving them their distinctive dark hue and rich roasted flavors.

- Munich Malt: Munich malt is used to add bready saltiness to beer; often found in German-style lagers and ales.

- Wheat Malt: Wheat malt is made by processing wheat grain instead of barley, giving it an irresistibly light and crisp taste in beer products. Wheat Malt can also add body to food recipes like pancakes.

What is Malt Used For?

Malt finds wide-ranging applications in the culinary and beverage sectors.

Most commonly it’s used in beer production but also used to make malted milk balls or malt vinegar products.

Malt in Beer

Malt is an integral component of beer, providing yeast with fermentable sugars they need to produce alcohol.

Malt also contributes significantly to its color, flavor and body; various kinds can even create different beer styles from light crisp lagers all the way through dark rich stouts!

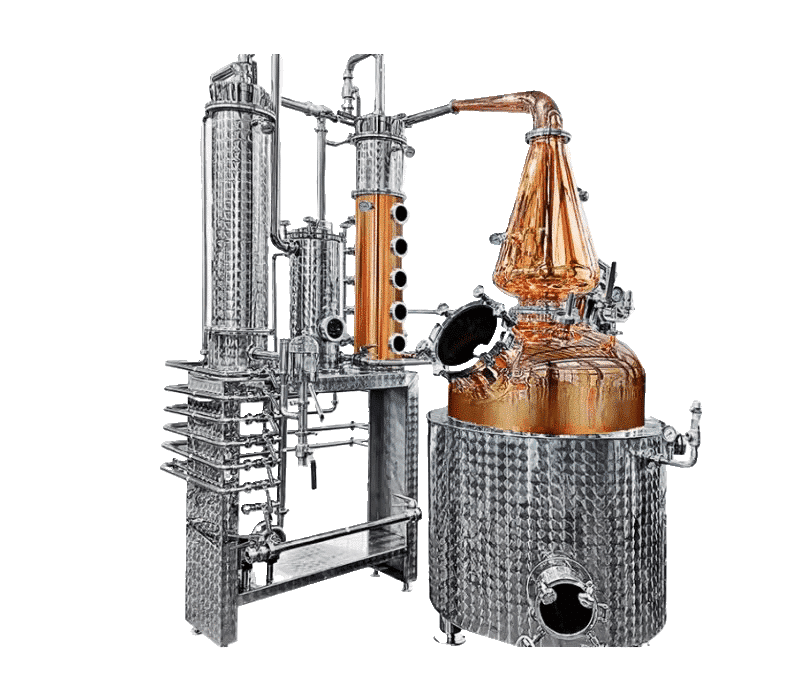

Malt in Whiskey

Malt is an integral component in producing whiskey; Scotch uses malted barley alone in its mash process for fermentation and distillation to make its product. Different malt varieties produce distinct tastes: heavily roasted malts create an earthy and peaty taste while lighter malts offer sweeter and subtler notes to your final product.

Malted Milk Balls

Malted milk balls (commonly referred to as malt balls), also a popular candy known as malt balls, are composed of malted milk powder mixed with chocolate and other ingredients for its distinctive taste and crunchy texture. Since their creation in the late 1800s, they have remained an irresistibly tasty treat!

Malt Vinegar

Malt vinegar, made of malted barley, is often used as an accompaniment for fish and chips in the UK; its versatility extends further, including use as salad dressing or marinade ingredient. Malt vinegar boasts an irresistibly tart aroma while often having darker tones than traditional varieties of vinegars.

How is Malt Made?

Malting, the process of producing malt, involves sprouting grain, drying it and roasting to produce different varieties of malts.

Here is a breakdown of this process.

- Steeping: Steeping the grains for an extended period in water is the first step of malting.. This activates the enzymes in the grain and begins the sprouting process.

- Germination: After soaking, the grain is spread out on a malting floor or in a germination box. Here, it is allowed to sprout for several days, during which time the enzymes in the grain convert starches into sugars.

- Kilning: Once the grain has sprouted, it is dried in a kiln to stop the germination process. The length of time and temperature at which the grain is kilned will determine the type of malt that is produced. For example, lightly kilned malt will produce a pale, lightly flavored beer, while heavily kilned malt will produce a dark, rich beer.

- Roasting: Some types of malt, such as roasted malt, are then roasted in a drum or oven to give them a darker color and more intense flavor.

- Milling: The final step in the malting process is to mill the malt, breaking it down into smaller pieces that can be used in the brewing or distilling process.

In the future, with the continuous development and innovation of the brewing process, the application fields and varieties of malt will also continue to expand, bringing more surprises and choices for our life.

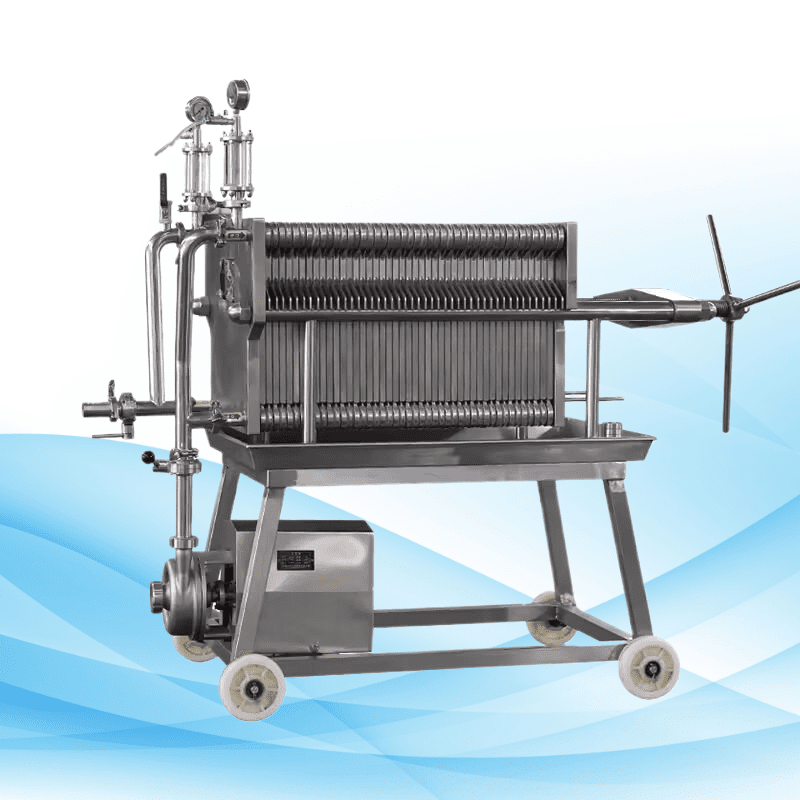

If you need to get a distillery equipment, please flow my catalog!