Explore the distinctions between pot still vs column still in distilling. Learn which still best enhances flavor, aroma, and purity in spirits, helping you choose the right distillation method.

What is a Pot Still?

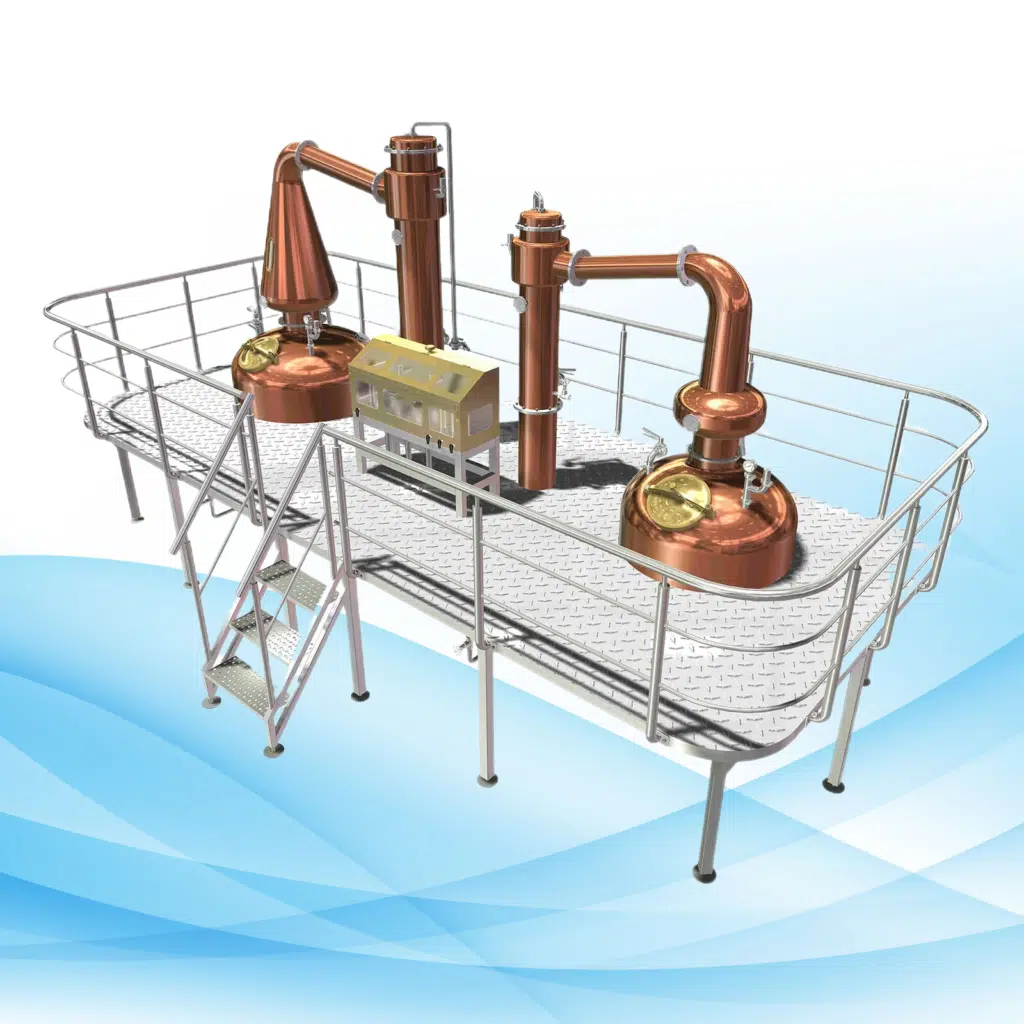

A pot still is a traditional type of still that contains one chamber, simple in design, but quite effective for certain distillation processes. It consists mainly of one large copper pot, where mash or wash is heated, and alcohol vapors consequently rise through a grooved swan neck and condense into liquid form once again.

- Composition: Single pot, swan neck, and condenser

- Material: Normally copper, to distribute the heat and remove impurities

- Ideal For: Spirits of richer flavor compounds, such as whiskey, rum, and brandy.

What is a Column Still?

Continuous stills, otherwise termed column stills, consist of a number of plates or trays placed vertically inside a column in which continuous distillation can occur. The vapor rises and condenses upon each successive plate, thereby yielding a distillate of high purity.

- Several plates, down comers, and columns

- Material: Stainless steel or copper

- Ideal For: Producing purer, lighter spirits like vodka and gin.

How Column and Pot Stills Work

How a Pot Still Works

In a pot still, one batch of heated wash alcohol evaporates at a lower temperature than water. It rises through the neck, condensing and flowing off as distillate. A high alcoholic content requires multiple distillations.

- Batch Process: One batch is distilled at one time.

- Slower Process: Generally slower, more labor-intensive

- Flavor Retention: It retains impurities that add complexity and richness to the spirit.

How a Column Still Works

With column stills, a continuous flow maintains the alcohol vapors always going up-the-plates and condensing on each one. Their purity increases owing to recondensation because of travel through every stage:.

- Continuous Process: Allows continuous distillation.

- High Purity: Makes the end product purer with fewer impurities.

- Efficiency: Fast production for high-volume distillation.

Pot Still vs Column Still: Key Differences

| Aspect | Pot Still | Column Still |

|---|---|---|

| Distillation Process | Batch, requiring multiple distillations | Continuous, with multiple columns |

| Flavor Profile | Rich, complex, retains congeners | Clean, light, fewer impurities |

| Speed | Slower, more labor-intensive | Faster, efficient |

| Alcohol Purity | Lower purity with distinct flavors | Higher purity, lighter taste |

| Best For | Whiskey, rum, brandy | Vodka, gin, lighter spirits |

Flavor and Purity

The two stills can most appropriately be differentiated by a number of factors, but one that stands out is the flavor and the purity. Among distillers, the pot still, because of its ability to retain distinct tastes from the raw materials, is regarded as one of the most important methods of distillation. On the other hand, column stills have the upper hand thanks to the high purity, since a lot of flavoring compounds are removed and clean spirits are produced.

Pros and Cons of Pot Stills

Advantages of Pot Stills

- Flavor Complexity: Congeners are preserved when distilling spirit liquor and contribute to the fuller/symer’s flavor.

- Ideal for Aged Spirits: These are more appropriate for spirits that require aging, such as whiskey and rum.

- Traditional Craft: These methods create a greater appeal for the smaller batch spirit makers, as pot stills are synonymous with artisan craftsmanship.

Disadvantages of Pot Stills

- Lower Efficiency: Pot stills require each batch to be distilled separately, which can be laborious and time-consuming.

- Limited Purity: Since most of the flavors are lost, several stills need to be used in order to obtain very high levels of alcohol concentration.

Pros and Cons of Column Stills

Advantages of Column Stills

- Higher Purity Levels: Almost all columns will produce distilled liquors of a light and clean taste due to the extreme amount of impurities removed.

- Efficiency: Prolonged distillation leads to better output and is thus more appropriate when looking at mass production.

- Versatility: Ideal for vodka, gin and even whiskey for a varying range of alcohol concentrations.

Column Stills Disadvantages

- Less Flavor: The number of flavor compounds decreases so that the number of complex elements present in some spirits might become less.

- Expensive Installation: It is also the case that since they are more complex, column stills are not cheap to install or maintain.

Which Still is Best for Each Type of Spirit?

- Whiskey: Whiskies are best produced through pot stills, as they tend to hold admirably strong flavor due to enhanced maturation.

- Rum: Aged rums are pot stills that have strong notes of deep molasses, but some lighter rums utilize column distillation.

- Vodka: Made out of column stills for the most part that permits the end product to be of high purity with no unique taste.

- Gin: It was also suggested to use a column still, as that would produce a light and clean distillate with the possibility of further infusion of botanicals.

Pot Still Vs Column Still

Artisanal and small-scale production: Pot stills suit small batch or unique small batch production that is quite labor-intensive but with satisfactions.

Mass production: In cases where there is a high demand and volume, however, column still operation is the preferred option.

Cost Considerations

pot stills are often low given the fact that there is a lesser initial cost burden but in the long term, it can incur higher labor costs as a result of batch processing.

However, in the case of column stills there will be huge investments to make at first, but the efficiency will be high enough to compensate and reduce the overall expenditure, especially where there is mass production.

Environmental Impact: Pot Still vs Column Still

While pot stills are more expensive to operate, column stills use less energy on average since they use a continuous type still and are therefore more efficient for higher outputs. However, for smaller distilleries using ethical artisanal methods, pot stills are however favored.

FAQs

- What Uh the difference between a pot still and a column still?

Most of the difference lies in their respective distillation processes. Pot stills are batch operated and spit out much fatter, flavor-bearing compounds, while column stills allow much simpler distillation in the mass production sense, as purity can be much higher, taste is much lighter.

- Which type of still is more suitable for whiskey?

Traditionally, pot stills are used in the manufacturing of whiskey, as it is able to cater the complex flavors of the spirit.

- Can you make vodka using a pot still?

Yes, it is certainly possible, but it will take a number of distillations to achieve the purity required for vodka, hence column stills are more suitable for the purpose.

- Why are pot stills preferred by craft distilleries?

Flavor and tradition are essential for crafts distilleries, and both these elements are provided by pot stills, hence they are widely used for artisanal spirits.

- Do you think that column stills are more environmentally friendly than other distillate types?

Yes, column stills are usually more energy-efficient, as its continuous distillation of liquid tends to lower its impact to a high-volume production run.

- Everything is fine, but how do I know what still is the right one for me?

If you value unique richer flavors and run on a small scale, a pot still may be perfect for you. However, for a large scale production of lighter spirits a column still will be most effective as well as the cleanest option.

Conclusion

In closing the discussion on the distinguishing features of pot and columns stills, the reader must understand that these two distilleries are distinct primarily based on body of the spirit, aromatic profile as well as production level. Whiskey and rum, which are called pot stills, are more robust and flavorful spirits, while vodka and gin are produced more effectively with column stills. The ability to comprehend these differences equips distillers with the ideal tools to ensure that all relevant equipment used guarantees that each spirit realizes it full potential.