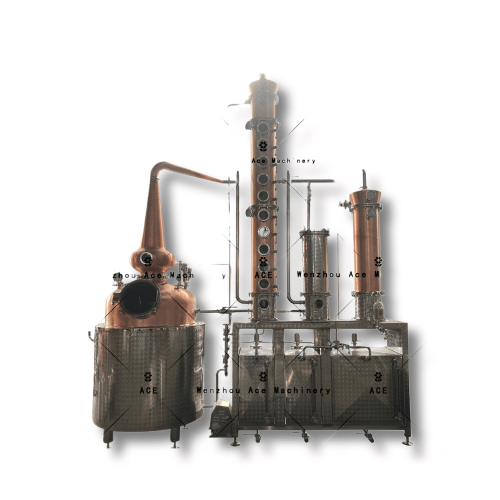

Custom-made Copper stills from 100 to 10,000 Liters

For high-level quality distillation, copper stills perform a core role. Copper stills are renowned for their exceptional removal of impurities and high-quality output of spirits. These stills are well adapted for specialized stripping and full product distillation with precision for spirits such as whiskey, gin, tequila and brandy. They can be customized to suit a variety of unique setups that include but are not limited to dephlegmators and condensers, which makes it range from small batch like an artisan all the way to commercial producers.

Video show

Key Components of a High-Quality Copper Still

The pot is the primary vessel for heating the mash. Copper is often preferred due to its excellent thermal conductivity and ability to remove sulfur compounds, enhancing the final product’s quality.

The goose neck, also called a helmet, captures and directs vapor to the column or condenser. Its shape and material (copper) influence the flavor and quality by eliminating unwanted compounds.

A gin basket allows for vapor infusion, essential for crafting gin and botanical spirits. Positioned before the distillation column, it imparts flavors from botanicals into the vapor, creating unique and balanced profiles.

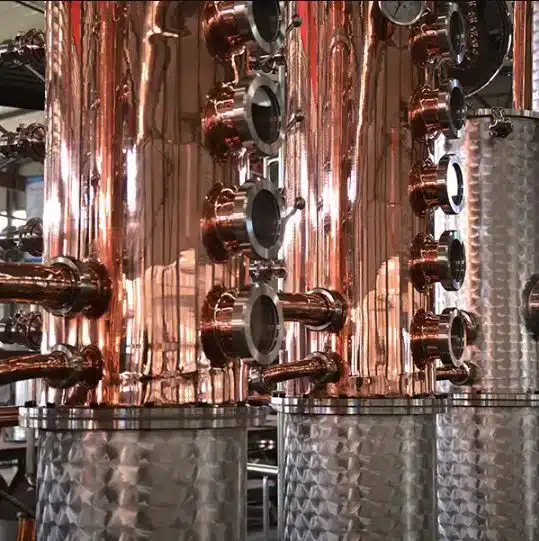

Distillation columns, available in both stainless steel and copper, increase purity by allowing vapor to condense and re-evaporate at each plate. Customizable to include 4–12 plates, they provide flexibility for producing spirits of varying purity and character.

The dephlegmator condenses vapor at the top of the column, allowing finer control of alcohol concentration and purity. Copper dephlegmators improve flavor and purity by eliminating sulfurous compounds.

The condenser rapidly cools the alcohol vapor, converting it back into liquid. This process ensures effective condensation, which preserves flavor while enhancing the clarity and purity of the distillate.

This component allows real-time measurement of alcohol concentration during distillation, helping to monitor and adjust the distillation process to achieve the desired results.

A dedicated support stabilizes the condenser, ensuring smooth operation and preventing leaks or mishaps during the distillation process.

Additional Options for Enhanced Performance

Customization options offer added control and versatility, helping distillers tailor their copper stills to meet precise requirements.

High-Torque Mash Agitator

For mashes that require additional agitation, a high-torque agitator prevents solids from settling, ensuring even heating and consistent distillation results. This agitator is especially useful in thicker mashes often used for whiskey or rum production.

Explosion-Proof Certification (CE/UL/CSA/ATEX)

For safety and compliance, especially in industrial setups, explosion-proof certifications ensure that stills are safe to use in potentially volatile environments.

Voltage Options

With voltage compatibility ranging from 110V to 600V and accommodating 3-phase 50/60 Hz setups, these copper stills can be tailored to fit a variety of electrical standards globally.

Additional Features for Optimal Functionality

- Copper Kettle and Dephlegmator/Condenser: Essential for adding flavor and removing impurities, copper components are preferred in all aspects of the distillation.

- CIP Pump and CIP Pipe: The Clean-In-Place (CIP) system enables easy maintenance, essential for keeping the still in optimal working condition.

- Bottom Spirit Storage Tank: A storage tank integrated at the bottom of the still provides convenience and efficiency, storing distilled spirits directly after condensation.

System Overview: Best Uses and Advantages

A copper still provides an excellent solution for a wide range of distillation processes. Here’s a quick overview of its best uses and advantages:

- Best Uses: Ideal for stripping runs, whiskey, brandy, tequila, gin, and rum production.

- Alcohol Content: Post-distillation alcohol content reaches approximately 70% ±10%, providing a robust, flavorful spirit.

- Versatility and Cost-Effectiveness: Copper stills offer high versatility, suitable for both artisanal and large-scale production.

- Easy Maintenance: With polished SS304 and brushed copper construction, these stills feature Clean-In-Place (CIP) systems that make upkeep and maintenance simple and efficient.