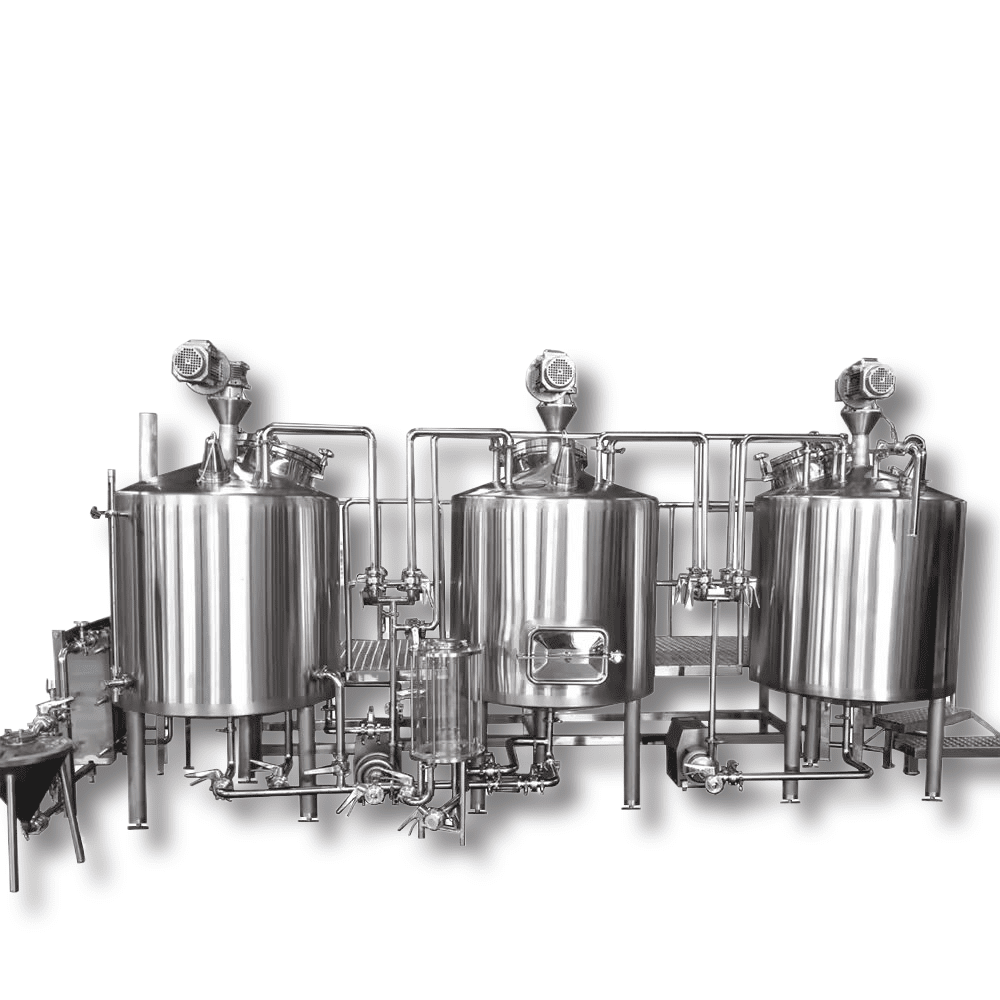

A 5 bbl brewing system is a type of brewing equipment used by craft brewers to produce 5 barrels (155 gallons) of beer at a time. It is a mid-sized system, making it a popular choice for small to medium-sized craft breweries.

Components of a 5-barrel Brewing System

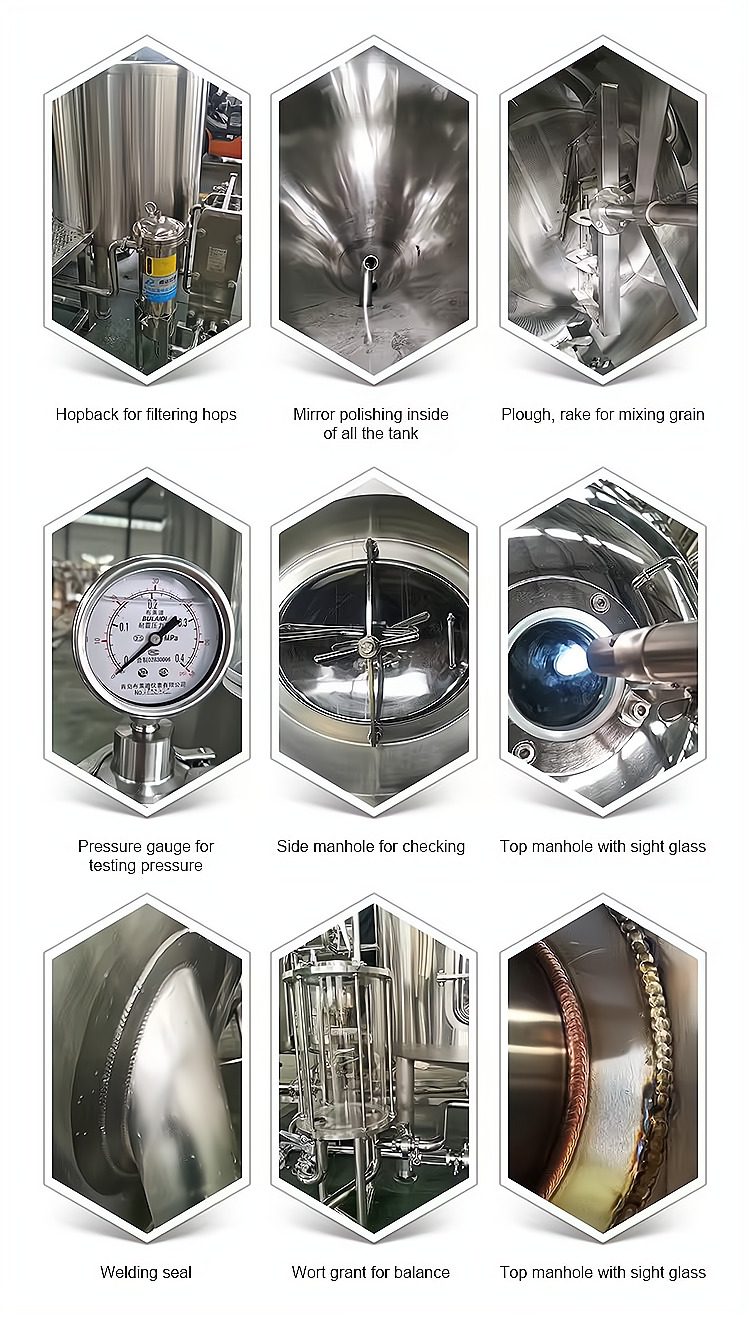

A 5-bbl brewing system consists of various components that work together to produce high-quality beer.

These components include:

Mash Tun

The mash tun is where the mashing process occurs, in which hot water and grains are combined to transform starches into fermentable sugars.

Brew Kettle

The brew kettle is where unfermented beer (wort) is cooked with hops and other additives to enhance flavor and aroma.

Hot Liquor Tank

The hot liquor tank heats and stores the water needed during the brewing process.

Fermentation Tanks

Fermentation tanks are where the wort is moved after being boiled and cooled. Yeast is introduced to the wort, and the fermentation process begins, converting the carbohydrates to alcohol and CO2. A 5 barrel brewing system often comprises numerous fermentation tanks, allowing multiple batches to be brewed simultaneously.

Bright Tank

The bright tank is where the beer is held after fermentation but before being bottled for distribution. It permits the beer to clear and carbonate before being placed into kegs or bottles.

How to Operate a 5 BBL Brewing System

Operating a 5-bbl brewing system may seem intimidating at first, but with proper knowledge and equipment, it can become an easy process.

- Milling: The first step is to mill the grains, breaking them down into smaller particles to expose the starches.

- Mashing: The mashing process takes place in the mash tun, where hot water and grains are mixed together to convert starches into fermentable sugars.

- Lautering: After mashing, the wort is transferred to the brew kettle, where it is boiled with hops and other ingredients.

- Cooling: Once the wort has boiled, it is transferred to the fermentation tanks, where it is cooled down.

- Fermentation: Yeast is added to the wort, and the fermentation process begins, converting the sugars into alcohol and carbon dioxide.

- Clarification: After fermentation, the beer is transferred to the bright tank, where it clarifies and carbonates.

- Packaging: Finally, the beer is packaged into kegs or bottles for distribution.

Our 5-barrel beer brewing system is extremely adaptable and expandable, enabling you to add or upgrade various accessories or modules – such as beer filtration systems and carbonation units – as needed to meet different styles and flavors of brewing.