Benefits of 7bbl brewhouse Equipment

- The equipment can be customized to the customer’s brewing methods and beer types.

- All Construction uses SUS304 stainless steel food grade, with a perfect inner and outer shell of 3mm.

- All tanks come with jackets that are specially designed to provide heating and cooling. The exchange area is large enough for both shell bottom and cone top jackets.

- The total volume of our tanks does not include cover headspace.

- Welding the tank is 100%TIG, all jackets are fully welded by water. The uniform cooling jacket dimples ensure long life and no leakage. All welds are passivated.

- We polish to Ra 0.4um, and can clean 360deg.

- Before packing, we will test the jacket for 12 hours in air and water. The jacket pressure is 5 bar, and the internal shell pressure is 4 Bar.

- All the testing records will be shown on our data when the tanks are shipped, along with the checking of the list and serial number to track.

- All components such as chillers, steam boilers, exchangers, and Schneider/ABB electronic control systems are of international brands. This ensures quality and convenience after sales.

Brewery Equipment 7bbl Standard Configuration

Malt Milling Unit

- Rolling Particle Crusher: Adjustable particle size for precise milling.

- Flexible or Steel Auger: Efficiently lifts milled grains directly into the mash tun.

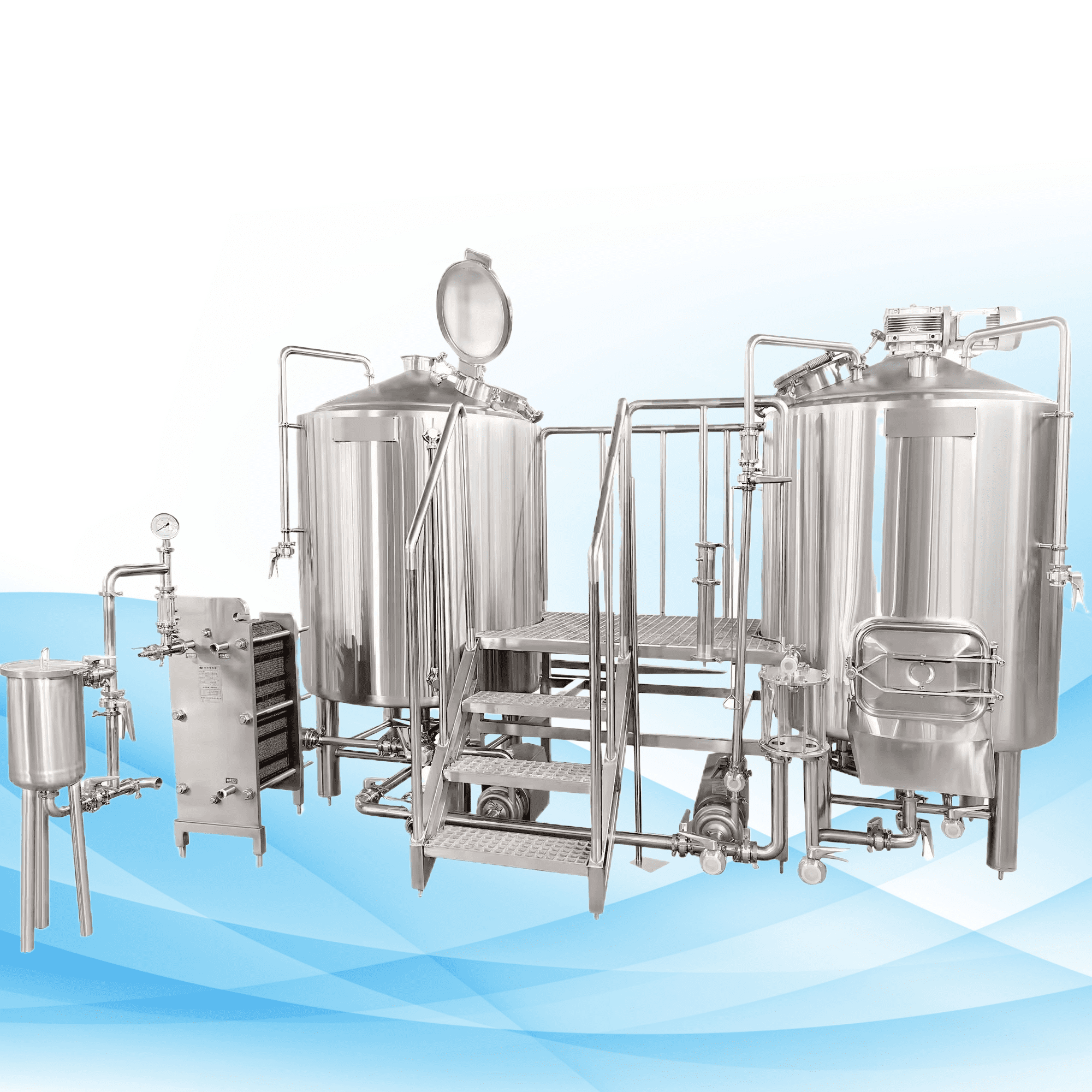

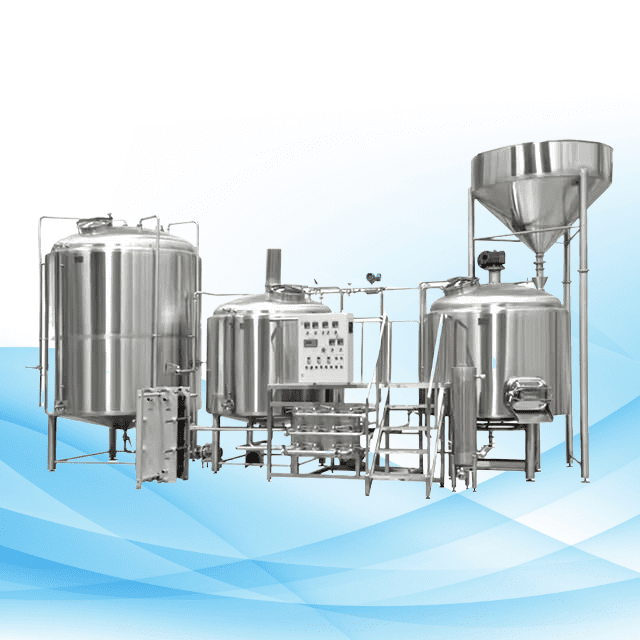

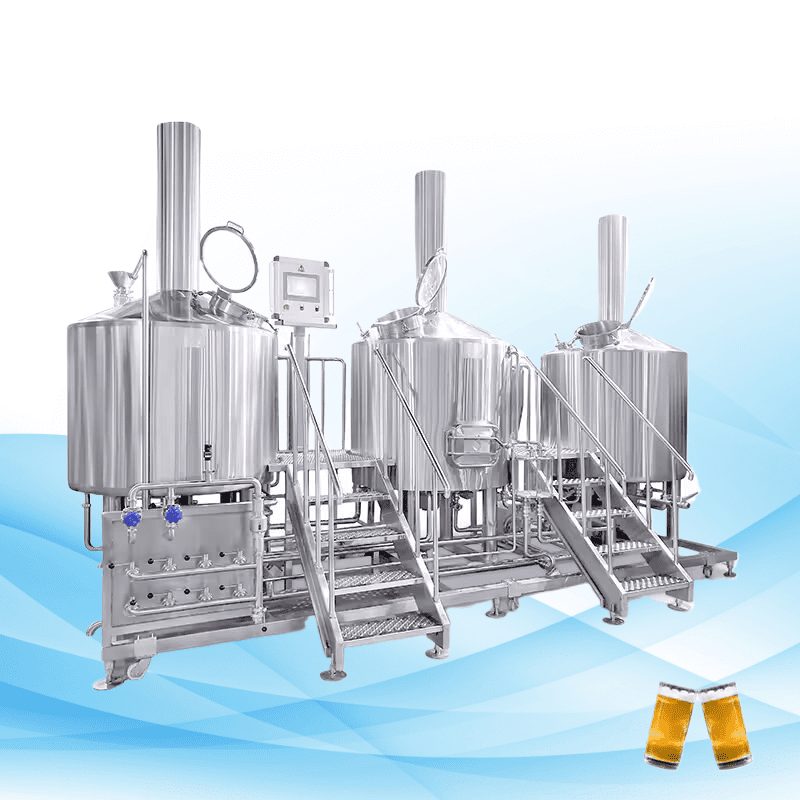

Brewhouse Unit

- Combination of Vessels: Includes Boiling/Whirlpool and Mash/Lauter tuns.

- Special Combinations: Available with hot water and cold tanks.

- Brewing Methods: Designed for both decoction and infusion methods to ensure exact brewing processes.

- Stainless Steel Construction: Popular for its easy maintenance, with optional copper cladding for an enhanced aesthetic.

- Heat Exchangers: Available in two-stage or one-stage for wort cooling.

- Integrated Work Platform: Made of durable stainless steel.

- Wort Pump: Sanitary and efficient for optimal performance.

- Complete Fittings and Piping: Ensures seamless operations.

Fermentation Tank Unit

- Conical Stainless Steel Tanks: High-quality and durable.

- Microbrewery Sizes: Available in single or double sizes to fit different brewing scales.

- Customized Tank Quantity: Based on the specific fermentation cycle of different beers.

- Included Components: All manholes, valves, and pressure gauges for comprehensive functionality.

Bright Beer Tank Unit

- Conical Stainless Steel Tanks: Similar high-quality construction as fermentation tanks.

- Microbrewery Sizes: Suitable for various scales, single or double-sized.

- Customized Tank Quantity: Tailored to the fermentation cycle.

- Included Components: Equipped with all necessary manholes, valves, and pressure gauges.

Cooling Unit

- Insulated Glycol Water Tanks: With or without copper coils for efficient glycol liquid mixing and holding.

- Refrigerators or Efficiency Chillers: Use freon as a cooling energy source.

- Centrifugal Pump: Sanitary design for recycling glycol water between tanks and heat exchanger.

- Complete Pipes and Fittings: Includes all necessary insulation materials.

Controlling Unit

- Brewhouse Electrical Control Cabinet: Features temperature and on/off controls.

- Cooling Parts Control Cabinet: Also includes temperature and on/off controls.

- Advanced Components: Thermocouples, solenoids, temperature controllers, and more.

- Optional PLC with Touch-Screen Panel: Available upon special request for advanced control and monitoring.

If you’re looking for reliable, efficient, and powerful beer production equipment, then 7BBL Brewery Equipment is definitely the place for you. Choose our brewhouse today and realize your dreams!