3bbl Beer brewing system Standard Configuration

Malt Milling Unit

- Particle adjustable rolling crusher

- Flexible or steel auger to directly lift the milled grain to mash tun

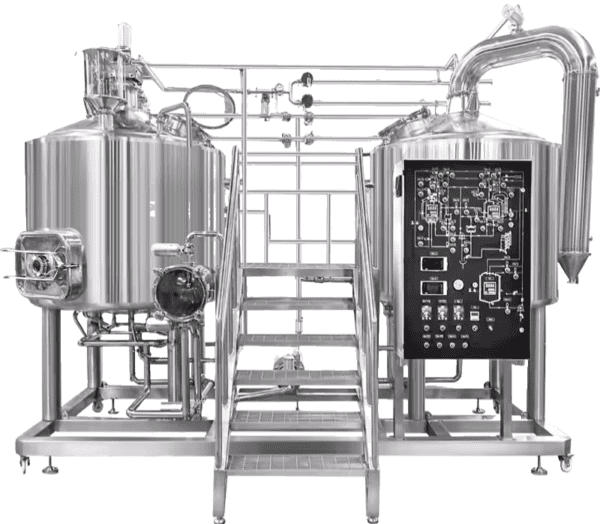

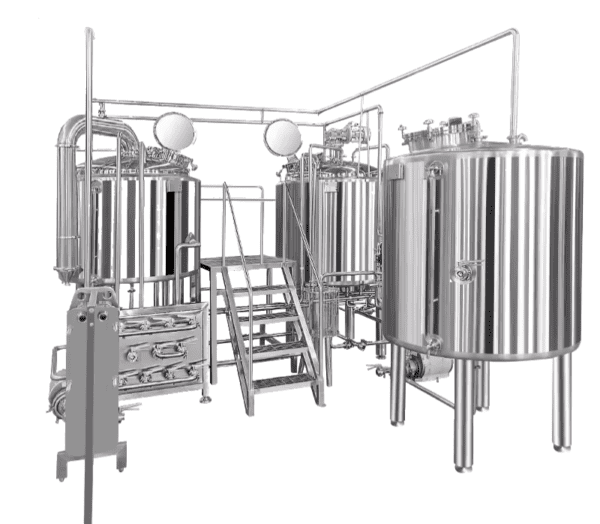

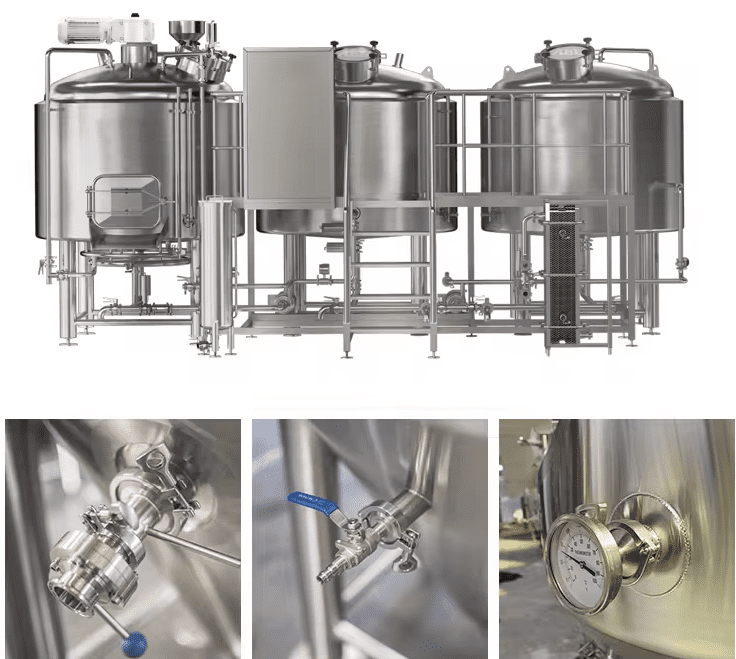

Brewhouse Unit

- Mash tun, Boiling/Whirlpool tun 2 vessel combination

- Copper ring or copper cladding for show as per customer’s installation place

- Hot water tank and cold water tank for optional in special combinations

- Infusion or decoction brewing methods are designed exactly

- Boiling process can be done under pressure, especially for brewery at higher altitude

- Two stages or a single-stage heat exchanger for wort cooling

- Completely stainless steel integrated work platform

- Sanitary and efficient wort pump VFD controlled

Fermentation Unit

- Conical stainless steel fermentation tanks

- Standard bright stainless steel tanks for maturation, conditioning and carbonation of beer

- Microbreweries commonly use brewhouses that are either single or double-sized.

- The exact tank quantity for different beers is calculated by the fermentation cycle

- All manhole, valves, pressure gauges, fittings, etc. All manhole, valves, pressure gauges and fittings are included

Cooling Unit

- Insulated glycol water tanks for holding and mixing glycol liquid

- Refrigerators or efficiency chillers with Freon as a cooling energy source

- Centrifugal pump with sanitary design for recycling glycol water between tanks and heat exchanger

- Solution for energy saving with CLT and HLT for wort cooling

Controlling Unit

- The PID system has temperature and on/off buttons for motor/pumps, as well as valves that can be operated manually.

- Automatic liquid level control, PLC touchscreen control system, measuring sparkling water accurately, temperature control, mixing water automatically, automatic liquid measurement, and automatic temperature control.

All in one beer brewing system Advantages

- The equipment can produce beer up to 33 Plato.

- Higher wort extraction, lower material consumption and higher efficiency, energy saving

- Automatic temperature, wort flow, and mash control.

- Construction of piping more rationally to reduce material loss and avoid the problem of wort aeration

- The jackets are specially designed to provide heating and cooling.

- The volume of the cover headspace is added to the headspace calculation for a larger headspace.

- Welding the tank is 100%TIG, all jackets are fully welded by water. The uniform cooling jacket dimples ensure long life and no leakage. All welds are passivated.

- The overall mirror polishing can be done by polishing the surface 6 times for a Ra 0.4um finish.

- Before packing, we will test the jacket for 12 hours in air and water. The pressure of the jacket is 5 Bar, that of the internal shell is 4 bar.

- All the testing records will be shown on our data when the tanks are shipped, along with checking the list of serial numbers and the quality control system.

- To ensure high quality and convenient afterwales, insist on using a high-end line of products to build our tanks. All components, such as chiller, exchangers, steam boilers, and Schneider/ABB electronic control systems, are all international brands.

All in one beer brewing system Specification

- Effective volume: 3BBL; Total volume: 3.75BBL

- Material: SUS304/SUS316 Stainless Steel

- Heating method: Electric/steam/direct fire heating

- Voltage: 3 phase/380 (220, 415,480…)v/50(60)Hz; Single Phase/220 (110, 240…)v/50(60)Hz

- Brewing batch: 1-2 brew/day

- Heat transfer efficiency: ≥90%

- Polishing accuracy: ≤0.4μm

- Heat exchange area: 0.45㎡

- Required area: 35m²