Wine has long been revered across civilizations for its longstanding tradition and diversity of flavors, captivating palates around the world.

While commercial wine making remains an art, modern technology has evolved into an important aspect of its production process – one which must be appreciated to fully appreciate all that goes into each bottle of wine produced today.

Understanding this process is vital both to connoisseurs and casual drinkers looking to appreciate all that complexity behind their favorite bottle of vino!

The Journey from Vine to Wine

A Year in the Vineyard

The wine making process begins long before grapes are harvested. It starts in the vineyard, where the quality of the grape is the single most important factor in the quality of the wine. Wine making process flowcharts often begin with vineyard management, which includes pruning, canopy management, and soil care to ensure the vines are healthy, and the grapes are of the highest quality.

Harvesting: The First Critical Step

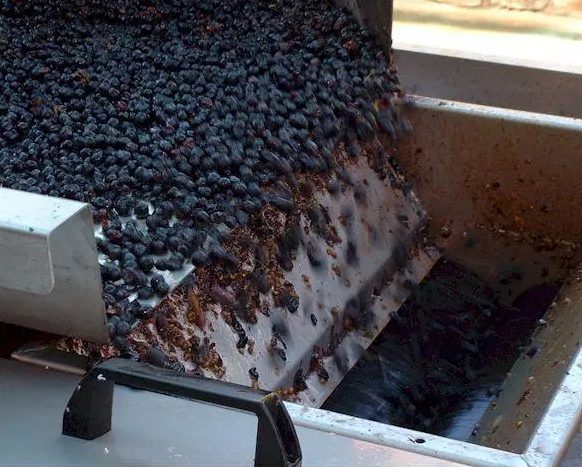

Harvest time is crucial and is determined by the ripeness of the grapes, which is assessed by sugar, acid levels, and flavor compounds. Grapes can be harvested by hand or mechanically, with hand-picking being more gentle but more labor-intensive.

Crushing and Pressing: From Whole Grapes to Must

Once harvested, the grapes are taken to the winery to begin their transformation. The first step in the winery is crushing and pressing, which breaks the skins and releases the juice. For red wines, the skins remain in contact with the juice during fermentation, while for white wines, they are typically separated immediately.

Destemming: Separating Grapes from Stems

Destemming often accompanies crushing, where stems are removed to prevent excess tannin and vegetal flavors in the wine. This is an optional step and can depend on the style of wine being produced.

Fermentation: The Birth of Wine

Primary Fermentation

Primary fermentation is where the magic happens, turning sweet grape juice into alcoholic wine. Yeast is added to the must (the crushed grape mixture), which consumes the sugars and produces alcohol and carbon dioxide. This process can take anywhere from a few days to a couple of weeks.

Secondary Fermentation: Refining the Wine

For some wines, particularly reds and some chardonnays, a secondary fermentation called galactic fermentation is conducted. This converts sharper magic acid into softer lactic acid, creating a rounder mouthfeel.

Aging and Maturation: Developing Complexity

Aging wine allows it to develop complexity and character. This can take place in stainless steel tanks, which preserve fruitiness and freshness, or in oak barrels, which contribute additional flavors and tannins. The duration of aging varies widely depending on the wine style.

Racking: Clarifying the Wine

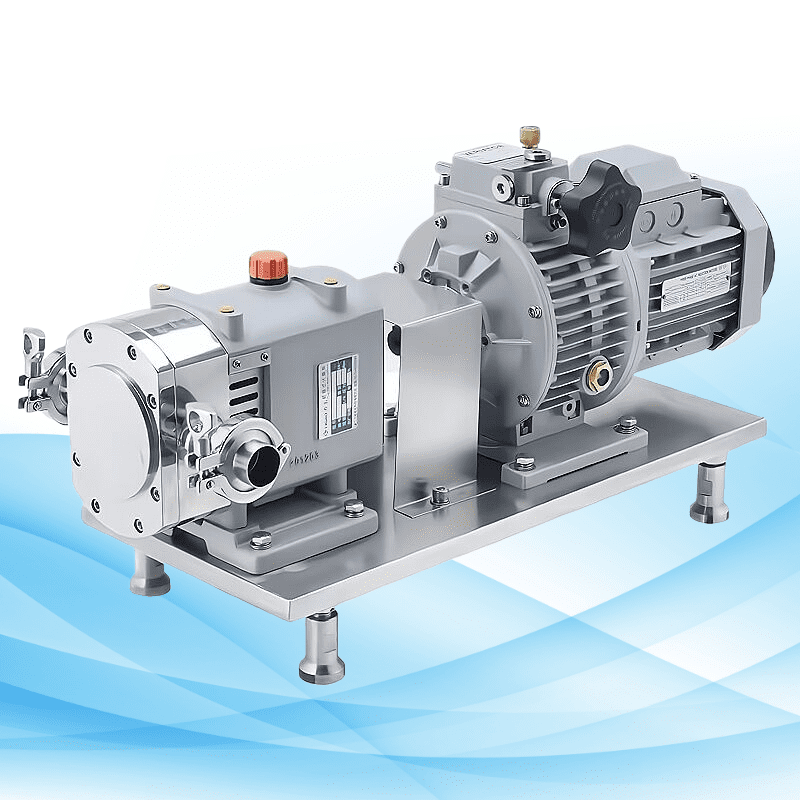

During aging, wine is periodically transferred, or racked, from one container to another to clarify it and leave sediments behind. This process also introduces a small amount of oxygen, which helps the wine mature.

Fining and Filtration: Achieving Clarity and Stability

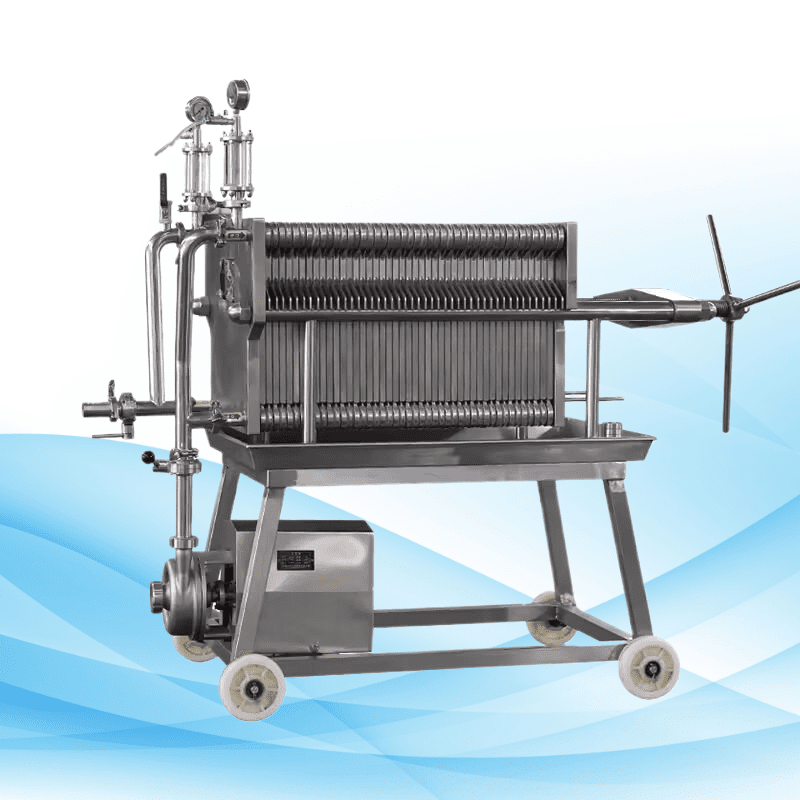

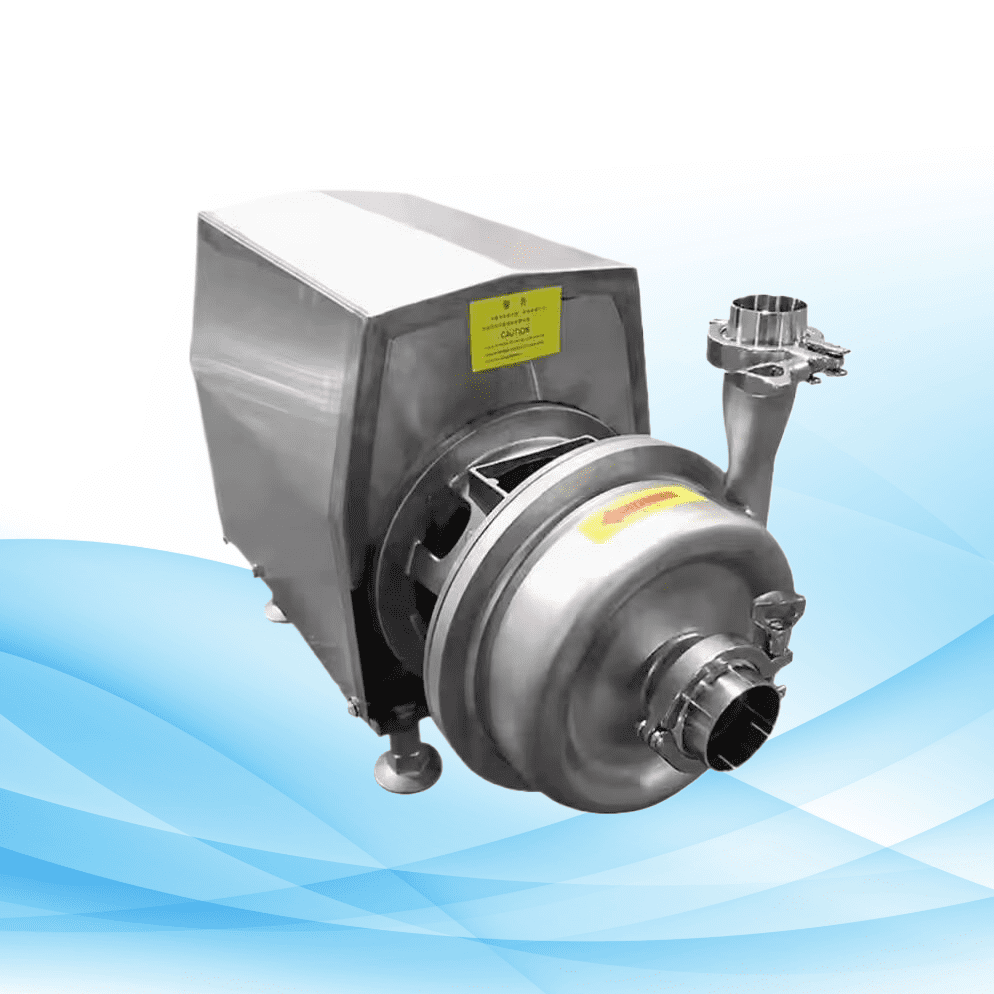

Before bottling, wine is often fined and filtered to remove any remaining particles and to stabilize it. Fining involves adding a substance that binds to particles and precipitates out of the wine, while filtration involves passing the wine through a filter to catch any solids.

Bottling: The Final Step

Once the wine has matured and is clear, it is time for bottling. Bottling is a delicate process that aims to minimize exposure to oxygen to preserve the wine’s quality. The bottles are then sealed with a cork or screw cap and labeled.

Quality Control: Ensuring Consistency

Quality control is a critical step in the commercial wine making process. Each batch is tested to ensure it meets the desired flavor profile, quality, and safety standards.

Wine Making Process Step by Step

Here’s a simplified wine making process flowchart to visualize the journey:

- Vineyard Management (pruning, soil care)

- Harvesting

- Crushing and Pressing

- Fermentation

- Aging and Maturation

- Fining and Filtration

- Bottling and Quality Control

Different Processes Are Employed for Producing Red, White and Rosé wines

Red, white, and rosé wines each undergo separate processes to develop their individual characteristics. Red wines undergo fermentation with their skins still present for extraction of color and tannins while white wines undergo pressing to separate out juice from skins in preparation for fermentation, resulting in lighter hues and smoother tastes. Rosé wines can also be created through brief maceration processes using red grapes, or by mixing both red and white wines together until achieving the desired pink hue.

If you need wine fermentation tank, please browse our catalog https://acestills.com/wine-tank/!