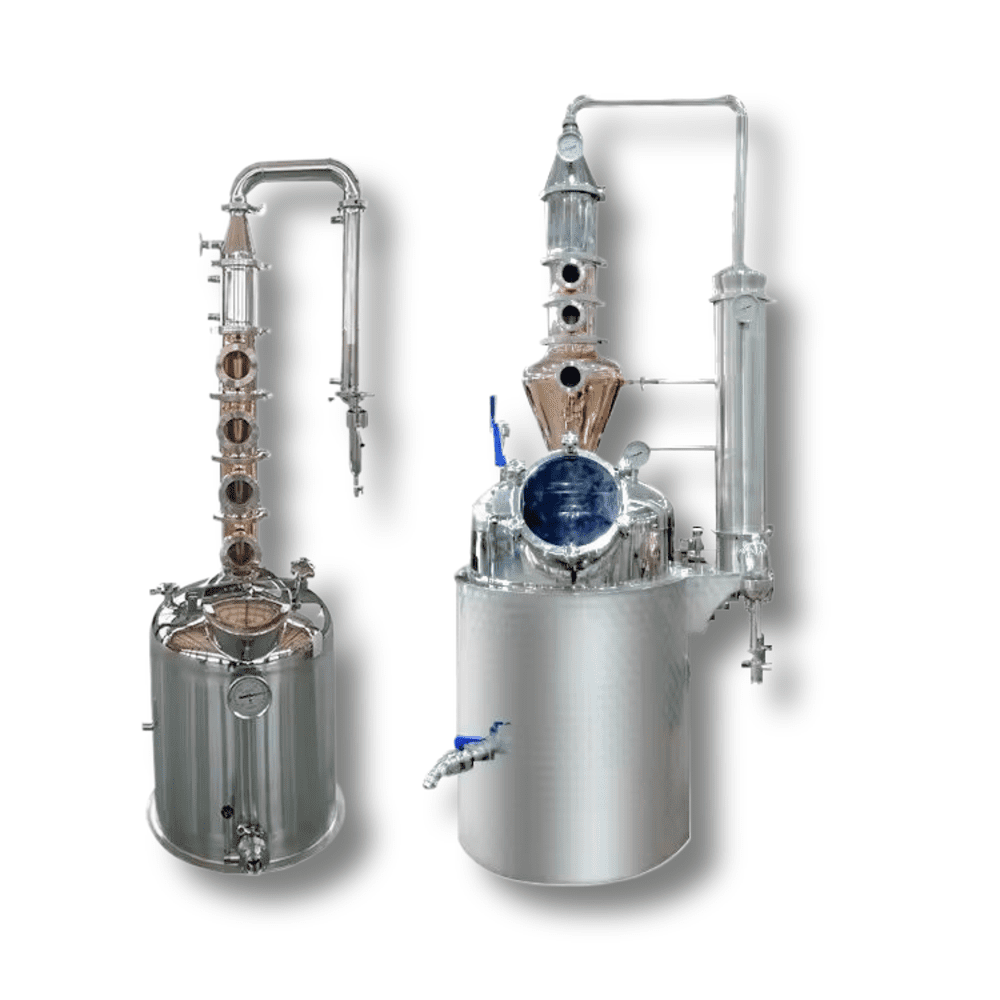

Pot Still Vs Reflux Still

In this article, we’ll compare pot stills and reflux stills as well as their designs, benefits and drawbacks, in depth.

Pot Still: A Traditional Approach

Pot Still (also called Alembic Still) is an ancient and centuries-old method. Consisting of a large copper pot with one chamber and long neck that’s heated from below to cause liquid to boil and evaporate into vapor form before being condensed back down into liquid form, the pot still is then passed to an alembic still for cooling before finally being disassembled again to collect liquid to use as raw materials for distillation.

Pot stills are ideal for creating whiskies and brandies, where maintaining certain flavors and aromas is of critical importance. Their simplistic design enables a high degree of manual control during distillation, enabling distillers to make precise cuts between heads, hearts, and tails as needed, often reflecting this craftsmanship in the character and complexity of spirits produced.

Design and Operation

A pot still is designed with ease of operation in mind, making it both straightforward and straightforward for any user to operate and maintain. Copper pots have long been utilized due to their ability to remove sulfur compounds and impurities from final products. Furthermore, multiple distillations processes can take place simultaneously to produce more concentrated spirits that offer enhanced flavors.

Pros and Cons of a Pot Still

Pros:

- Simple design that is easy to operate and maintain

- Copper material helps remove impurities and produces a more flavorful spirit

- Multiple distillations can result in a more concentrated and flavorful spirit

- Ideal for producing spirits with complex flavor profiles, such as whiskey and brandy

Cons:

- Batch process can be slower compared to reflux stills

- Less control over the distillation process

- Less efficient in terms of alcohol yield

- May require more manual intervention during operation

Reflux Still (Column Still)

The reflux still, also referred to as column still, is an innovative design which has gained prominence recently. Consisting of a tall column made of copper or stainless steel with multiple chambers or plates inside, its bottom heated in order to cause liquid in it to boil upwards through these chambers; once at the top it condenses back onto itself, creating an ongoing distillation process.

Reflux stills are often chosen for large-scale commercial operations due to their efficiency in producing high-proof spirits, such as vodka or gin, that requires consistency and purity in production. Furthermore, their continuous distillation process allows for consistent output production by distilleries looking for higher output levels.

Design and Operation

A reflux still is more complex to design and operate than its pot still counterpart, yet allows more control of the distillation process. Multiple chambers or plates inside its column enable separation of various components in the liquid to produce more pure spirits with higher alcohol yields. Copper allows for lower operating costs but produces inferior spirits overall.

Pros and Cons of a Reflux Still

Pros:

- More control over the distillation process

- Higher alcohol yield compared to pot stills

- Continuous process results in a faster distillation rate

- Produces a purer and more consistent spirit, ideal for vodka and gin

Cons:

- More complex design and operation

- Less flavorful spirit compared to pot stills

- Higher initial cost due to the use of stainless steel

- May require a greater technical understanding of operating effectively

Which is Right for You?

When deciding between a pot still and a reflux still, it ultimately comes down to personal preference and the type of spirit you are looking to produce. If you are looking for a more traditional and flavorful spirit, a pot still may be the better option. However, if efficiency and control over the distillation process are important to you, a reflux still may be the better choice.

Consider the scale of your operation, the desired flavor profile of your spirit, and the level of expertise you have in distilling. A pot still might be more suitable for small-batch, artisanal distilleries, while a reflux still could be the best fit for larger, industrial operations focused on producing neutral spirits.

Conclusion

Both pot stills and reflux stills have their own unique benefits and drawbacks. The traditional design of a pot still may appeal to some, while the modern and efficient design of a reflux still may be more appealing to others. The main distinction between them lies in the addition of chambers or plates in a reflux still, which provides greater control of distillation processes and higher alcohol yield. Whichever you choose, both types of stills can produce high-quality spirits with the right techniques and ingredients.