Brandy, that aged fruit spirit that’s distilled to give it those killer flavors, has a really long history. You know, the kind of drink you should sip slowly to really get all its layers of complexity. With the right tools and a bit of patience, you can create your own exclusive spirit.

This guide is going to show you how to make brandy from start to finish – from picking the fruit to popping it in a bottle.

Learn what equipment is necessary, how to ferment and distill alcohol, as well as the distinct flavor changes as your batch ages, and plus we will discuss brandy’s history, different varieties and its significance across cultures.

No matter if you are passionate about home brewing or simply curious to understand the creation process of brandy. This guide is here for all.

Understanding Brandy: Origins and Types

Before diving in and making brandy, let’s first learn what brandy is and its history – this will allow us to gain a greater appreciation for what’s to come when creating it!

What is Brandy?

Brandy is an alcoholic spirit distilled by distilling wine or fruit juice fermented over time, such as raisins. The term ‘brandy’ derives its name from Dutch word brandewijn which translates as ‘burnt wine” due to heat used during the distillation process.

Brandy can trace its roots back to Ancient Greece, though its widespread adoption started during the 14th century in France and Spain when distillers began distilling wine with water to create an easier to transport and longer shelf-life product – brandy.

Different Types of Brandy

Each type of brandy offers something distinct; fruit types used, the distillation method employed and age all play their parts to determine its flavor profile.

- Cognac: Produced in France’s Cognac region, this brandy is produced using white wine distilled into spirits before ageing it for at least 2 years in oak barrels.

- Armagnac: Similar to Cognac but aged for longer to achieve deeper flavors and an irresistibly smooth experience, Armagnac has proven popular worldwide.

- Fruit Brandy: This type of brandy is made from a variety of fruits, such as apples, cherries, or peaches.

- Pisco: A South American brandy made from grapes, Pisco is usually not aged, resulting in a clear, fresh spirit.

Understanding these types will help you decide what kind of brandy you want to make. Whether you’re aiming for a traditional grape brandy or want to experiment with different fruits, the choice is yours.

Essential Equipment for Making Brandy at Home

To successfully make brandy at home, some specific equipment will be required – specifically a still, fermenting vessels and containers to store or age your product.

Choosing the Right Fruit

The first step in making brandy is choosing your fruit. The type of fruit you choose will significantly impact the flavor of your brandy.

Brandy is traditionally made from grapes; however, you can substitute any fruit with high sugar content for brandy production – including apples, pears, peaches, and cherries. When selecting fruit to use for making brandy, quality matters – so choose fruit that ripens well; that way your brandy will taste even better!

Preparing Your Home Distillery

Once you’ve chosen your fruit, it’s time to prepare your home distillery.

A list of the essential equipment you’ll need:

- Fermentation Vessel: This is where you’ll ferment your fruit into wine. It needs to be large enough to hold your fruit and liquid, and it must be sealable to prevent contamination.

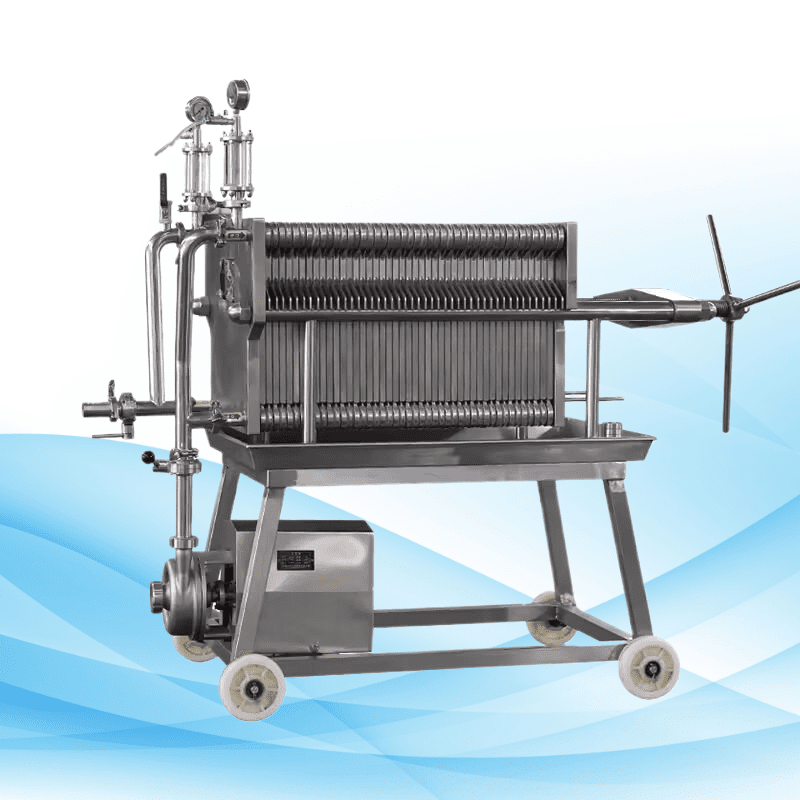

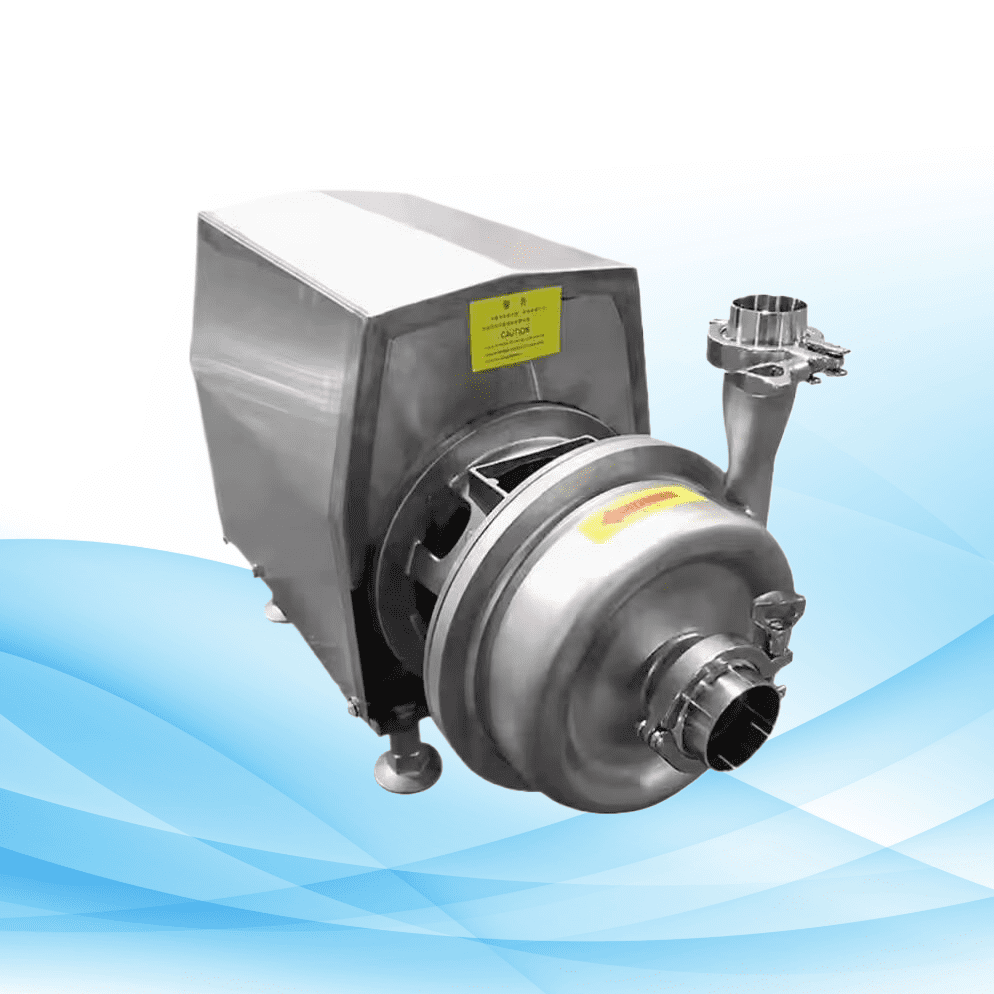

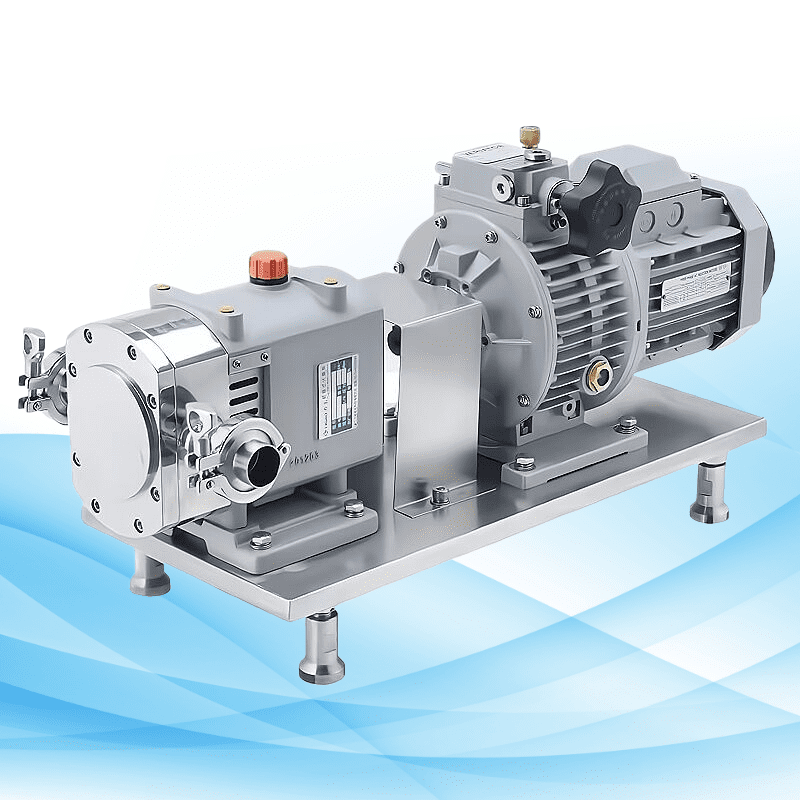

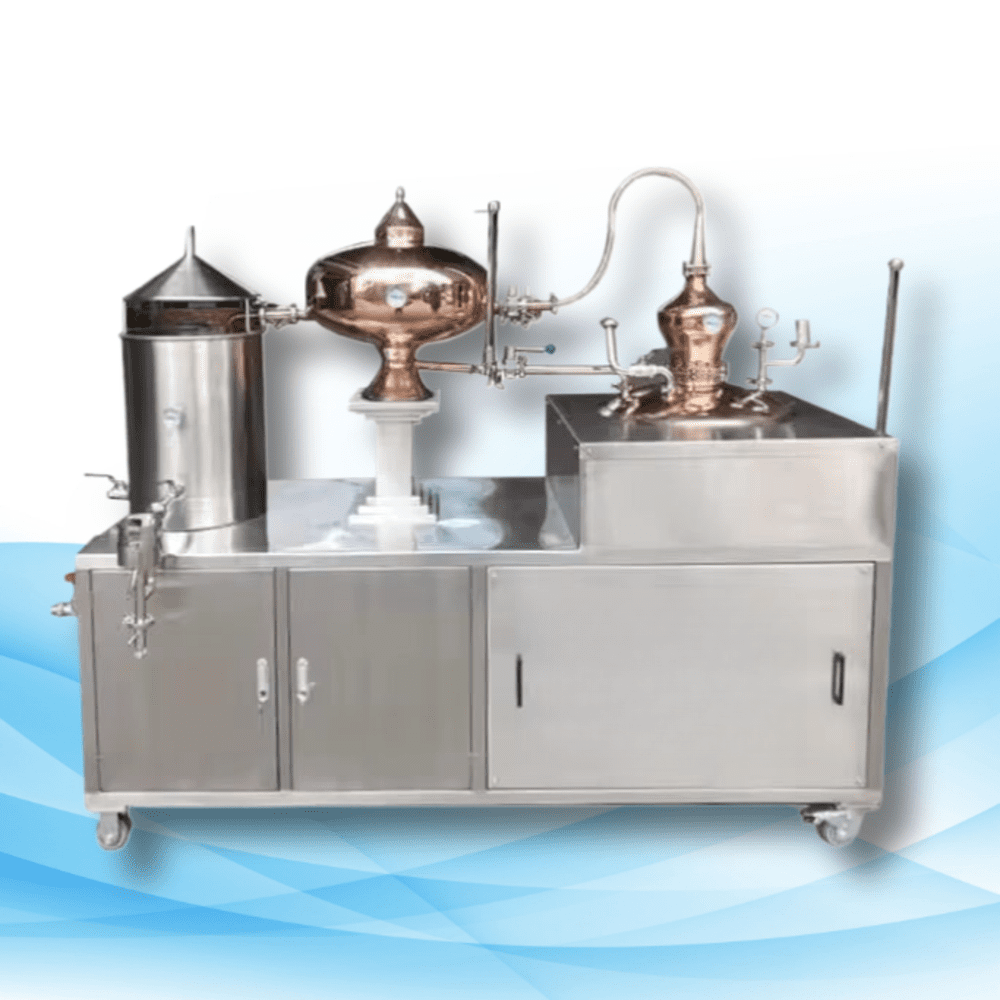

- Still: The still is used to distill the wine into brandy. There are many types of stills available, from simple pot stills to more complex column stills.

- Hydrometer: This tool measures the specific gravity of your liquid, which helps you determine the alcohol content.

- Thermometer: A thermometer is essential for monitoring the temperature during fermentation and distillation.

- Aging Containers: After distillation, your brandy must be aged before being stored for consumption. Oak barrels are often chosen, although other wood species such as cedar can also be utilized.

Cleanliness is of importance during distilling, so be sure to thoroughly disinfect all equipment used and prevent bacteria or yeasts from infiltrating it and ruining your brandy.

The Brandy Making Process: A Step-by-Step Guide

Making brandy at home can be both enriching and satisfying; with patience, hard work, and careful consideration it yields something truly exceptional that you can share with loved ones and savour together.

Step 1: Selecting and Preparing Your Fruit

The first step in making brandy is selecting and preparing your fruit. As mentioned earlier, you can use any fruit with a high sugar content.

Once you’ve chosen your fruit, you’ll need to wash it thoroughly. Then, remove any stems or leaves and cut the fruit into small pieces. This will help the yeast access the sugars during fermentation.

Step 2: Fermentation Fundamentals

The next step is fermentation. This is where the sugars in the fruit are converted into alcohol by yeast.

Start fermentation by placing your prepared fruit in the fermentation vessel, adding water and yeast according to how much fruit there is being processed. You should adjust accordingly depending on how many cups are being fermented at one time.

Here are the basic steps for fermentation:

- Add Fruit: Place your prepared fruit in the fermentation vessel.

- Add Water: Add enough water to cover the fruit. The exact amount will depend on the size of your vessel and the amount of fruit.

- Add Yeast: Sprinkle yeast over the fruit and water. The yeast will start to consume the sugars in the fruit and convert them into alcohol.

Cover the fermentation vessel and let it sit at room temperature. Fermentation may take anywhere from one or two days up to several weeks, depending on the fruit used and climate conditions.

Step 3: Distillation – The Heart of Brandy Making

Once fermentation is complete, it’s time for distillation. This is where the alcohol is separated from the rest of the liquid.

To distill your brandy, you’ll need to transfer the fermented fruit and liquid (now a type of wine) into the still. Then, heat the still to start the distillation process. As the liquid heats up, the alcohol will start to evaporate. The vapor will then condense back into a liquid, which is your brandy.

During distillation, you’ll need to make ‘cuts’. This means separating the ‘heads,’ ‘hearts,’ and ‘tails’ of the distillate. The ‘heads’ contain harmful alcohols and should be discarded. The ‘hearts’ are the best part of the distillate and will become your brandy. The ‘tails’ contain flavors that can be harsh and are usually discarded or re-distilled.

Step 4: Aging Your Brandy for Excellence

Once distillation has taken place, brandy must be aged to give its distinctive flavors and characteristics a chance to develop and mature further, giving brandy its characteristic flavors.

Aged brandy typically undergoes its maturation process in oak barrels. Over time, brandy absorbs its surroundings to form its flavor profile; each sip becomes increasingly complex over time! Drinking it becomes like embarking on an incredible voyage! Aging time varies based on individual preferences, ranging anywhere from months up to several years.

As part of its aging process, brandy should be stored in a cool and dark area in order to slow the oxidative aging process and allow its flavors to fully develop. This also keeps costs lower.

Step 5: Bottling and Storing Your Brandy

Once your brandy has aged to your liking, it’s time to bottle it.

Use a funnel to transfer the brandy from the aging container to your bottles. Before beginning, ensure all bottles are clean and dry. Once the brandy is bottled, seal the bottles with a cork or cap.

Store your bottled brandy in a cool, dark place. Proper storage will help preserve the flavor of your brandy and can even allow it to continue aging and developing in the bottle. Enjoy your homemade brandy responsibly and share it with friends and family to celebrate your accomplishment.

Legal Considerations and Safety Precactions

Before you start making brandy at home, it’s important to understand the legal considerations. In many countries, including the United States, home distillation of alcohol is illegal without a proper license.

Due to safety regulations and tax restrictions, distilling alcohol requires following strict protocols in terms of both safety and tax regulations. Since alcohol distilling involves working with potentially flammable materials that could become explosive if done incorrectly, following safety protocols while selecting and using appropriate equipment are absolutely key elements in succeeding with any distilling project.

If you are keen on making brandy at home, make sure that it complies with local or state regulations before doing so. In certain countries it may only be legal for wine or beer production but not spirits distillation at home; ensure both safety and legal compliance before embarking upon home distillation as an artform.

Troubleshooting Common Brandy Making Issues

Making brandy at home can be a rewarding experience, but it’s not without its challenges. One common issue is a stuck fermentation, where the yeast stops converting sugar into alcohol. This can be caused by a lack of nutrients, incorrect temperature, or an unsuitable yeast strain. If this happens, try adjusting the conditions or adding a yeast nutrient.

Another common problem is off-flavors in the final product. This can be due to poor quality fruit, incorrect cuts during distillation, or issues with the aging process. Always use ripe, high-quality fruit and be careful when making cuts to separate the ‘heads,’ ‘hearts,’ and ‘tails’ during distillation.

As with anything worthwhile, successful brandy production requires practice. Don’t become disheartened if your first few batches don’t turn out quite right – simply experiment further until your process improves with time.

FAQs: Answering Your Brandy Making Questions

Brandy making can be a complex process, and it’s natural to have questions. Here are answers to some of the most common queries:

- Which fruit can I use to create brandy? Any fruit can be used, although traditionally grapes have long been preferred as the base material for brandy production. Apples, pears, and peaches may also make tasty choices when creating this spirit-laden spirit!

- How long does it take to produce brandy? Fermentation usually lasts about one or two weeks; distillation requires several hours; while aging could range anywhere between several months to several years.

- Can I make brandy without using a still? In theory yes; however it will likely prove more challenging and the results may not be as rewarding; thus a still is strongly suggested as it offers optimal results.

Make no mistake about it – successful brandy making requires patience and practice! Don’t be scared to experiment and learn from any missteps along the way – happy distilling!

For commercial brandy distilleries, browse our equipment catalog at https://acestills.com/products/